Browse Course Material

Course info.

- Prof. Lionel C. Kimerling

Departments

- Materials Science and Engineering

As Taught In

- Electrical Engineering

- Electronic Materials

Learning Resource Types

Principles of engineering practice, case studies.

Case Study and Project Reports will be presented by the assigned Teams. The process is as follows:

Prof. Kimerling will lead a short in-class discussion on the approach for each Case Study or Project. Q&A is encouraged to clarify specific details.

The Instructors and TAs will moderate online Discussion Forums: within this Forum students should post their team’s tentative outline, develop concepts, discuss sources and preliminary findings. Instructors and TA will provide feedback within this Discussion Forum.

An optional office meeting with Prof. Kimerling is available if desired by any Group.

On the day of presentations, each Group must present a 20 minute presentation of 5-6 slides. Each member of the Group must present one slide from this presentation. Slides must be posted to the Web site the night before.

Students are expected to bring hard copies of all presentations to class.

Corrected slides and a final 2-page report must be posted to the Web site two days after presentation.

Grade assignment for the Case Studies and Projects will account for the following:

- presentation and writing skills

- clarity and rationality of the design execution

- presentation of background, issues, alternatives and conclusions

All student work is presented with permission of the authors.

| Assignments | Resources |

|---|---|

| An Ethical Engineer? ( ) | Pinker, Steven. “ .” New York Times, January 13, 2008. |

| Big Infrastructure Engineering ( ) | |

| Social Construction of TV History ( ) | |

| Semiconductors and Learning Curves; Steel Technology and Big Infrastructure ( ) | “Semiconductors and Learning Curves.” ( ) “Steel Technology and Big Infrastructure.” ( ) |

You are leaving MIT OpenCourseWare

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- ADVERTISEMENT FEATURE Advertiser retains sole responsibility for the content of this article

A case study in development of material science

Produced by

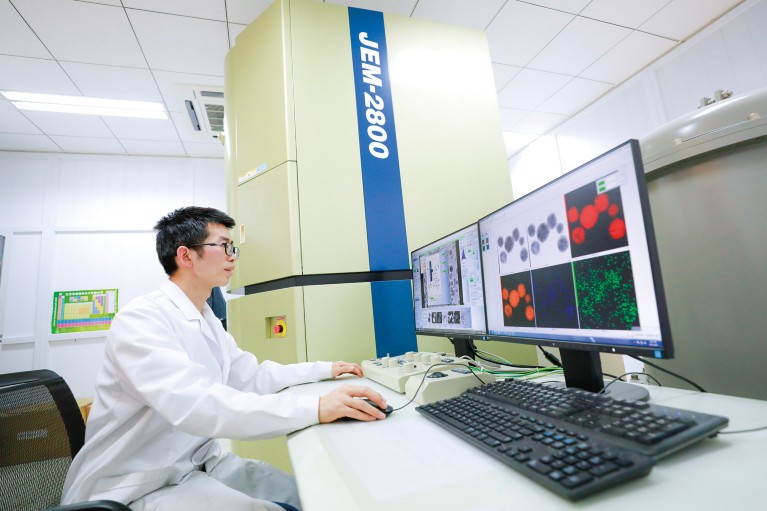

Credit: Nankai University

China’s significant increase in research investment has already brought a boom in the country’s research output. The gains are probably best illustrated in the field of material science, in which the number of publications has grown from almost none in the early 1980s to the largest in the world now. With applications ranging from manufacturing and electronics, to energy and biomedicine, material science is of profound interest to government funders and a field on which national economies rely heavily.

Data from the Essential Science Indicators (ESI) in 2018 show that Nankai is ranked among the global top 1.2‰, or 97th, in material science, up from 116th in mid-2017. It leads among Chinese universities in the number of citations per publication in journals listed in the Science Citation Index (SCI). Two MSE faculty members were listed among the 2018 Global Highly Cited Researchers by Clarivate Analytics.

Booming research results

One area of leading research performance at MSE is rare earth functional materials, with 30 highly cited papers tracked by ESI. “China has abundant rare earth resources, but a comprehensive scheme for using them is yet to be developed,” said Yan Chunhua, a member of the Chinese Academy of Sciences (CAS), and head of the MSE’s Centre for Rare Earth and Inorganic Functional Materials. The centre’s researchers develop novel technological processes of rare earth products and explore new applications of rare earth materials, ranging from energy and catalysis, to high-precision manufacturing and sensors. Their results have led to more than 10 patents.

Prize-winning science

At the MSE Centre for Optical, Electrical, and Magnetic Materials, Bu Xian-He, the centre head and dean of MSE, leads a group that focuses on constructing inorganic solid materials for energy storage and conversion. They won the second prize of the National Natural Science Award in 2014 for their work on the synthesis, structure modulation, and properties of coordination polymers. Researchers at the centre also work on inorganic-organic hybrid magnetic and polymer materials, and construction of functional molecular aggregate materials.

MSE researchers on new catalytic materials have established a new methodology for characterizing highly active intermediates in catalytic reactions by integrating technologies of chemical capture, spectroscopic analysis and computational simulation, which has facilitated the study of molecular sieve materials. They have also developed the AlPO-34 molecular sieve, a crystalline material with regular pores the size of a molecule for catalysis. Their results have gained 20 national patents.

To meet growing needs for new materials and devices for information and energy, researchers at the MSE Centre for Photonics/Electronic Materials have made progress in silicon-based illumination devices. They have designed nano-layered compound films with specific photoelectric properties and developed their applications in sensors, supercapacitors and other devices.

Outlook to the future

In an effort to develop cross-disciplinary and application-based research, the school is growing its computational materials science and materials genome research. Investments are also being made to advance research on biomedical, environmental, and intelligent materials and devices to better meet societal demands. In educational programmes, MSE encourages the integration of natural science and engineering to form interdisciplinary teams.

As Nankai University has received government support for building a world-class university, MSE is leveraging university and government resources to expand its current provincial and national key research platforms. Continual investment and infrastructure support will ensure a vibrant future for MSE.

+86 (0)22 85358786

http://mse.nankai.edu.cn

Quick links

- Explore articles by subject

- Guide to authors

- Editorial policies

- Hispanoamérica

- Work at ArchDaily

- Terms of Use

- Privacy Policy

- Cookie Policy

Pushing Boundaries with Bamboo: A Structural Engineering Case Study

- Written by Rodrigo Istchuk

- Published on September 26, 2023

In a world grappling with environmental challenges, forward-thinking architects and engineers are increasingly leaning towards more sustainable solutions. While steel and concrete have long dominated the construction industry, bamboo is now stepping into the limelight as a compelling alternative. Thanks to its potent mix of strength, flexibility, and eco-friendliness, bamboo is fast becoming the go-to material for those keen on pushing the boundaries of sustainable architecture.

Bridging this transformative moment in sustainable design is the timely arrival of the "Bamboo Structures" eBook series, which this article is based on. Acting as a touchstone in the field, the first volume focuses on the structural design process behind the Luum Temple —a masterclass in bamboo engineering. The guide serves as more than just a theoretical text; it is a comprehensive manual teeming with real-world insights, cutting-edge research, and practical expertise.

The use of bamboo as a structural material is far from a new phenomenon; it has a rich history that stretches back thousands of years. Despite its ancient roots, much of this traditional knowledge has been underestimated as the modern construction sector became overly focused on mineral-based materials. Today, however, bamboo is experiencing a global resurgence, bringing to light a harmonious blend of ancient wisdom with modern engineering. This fusion not only offers new avenues for sustainable architecture but also feels like a long-awaited, inevitable evolution of the construction industry.

The Luum Temple: An Icon of Sustainable Design

Nestled in the lush landscapes of Tulum, Mexico, the Luum Temple is more than just an eye-catching architectural marvel; it's a pioneering example of what happens when traditional wisdom meets modern engineering. Designed to stand against 250 km/h hurricane winds and significant seismic forces, this structure embodies the compelling possibilities that arise when we harness bamboo’s unique properties as a structural material.

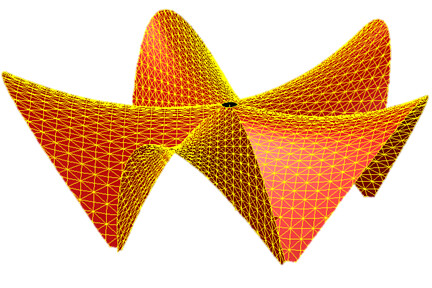

The architectural vision was conceptualized by the CO-LAB Design Office , brought to life by Architectura Mixta , and inspired by the iconic work of legendary architect Felix Candela . The engineering was led by Esteban Morales , who describes the structural system as five intersecting hyperbolic paraboloids made of bamboo arches and split bamboo beams.

Bamboo’s tensile strength-to-weight ratio often surpasses that of steel, making it not just strong but also lightweight. Flexibility is another advantage: especially when used in split form, bamboo enables architects to craft organic, flowing shapes that defy traditional geometrical constraints, facilitating the adoption of innovative structural approaches that rely on shape stiffness and biomimicry. Bamboo ’s rapid growth and ability to sequester carbon also position it as an environmentally superior alternative to traditional construction materials, including timber.

On the other hand, working with bamboo also requires special care in certain aspects. Due to its lightweight nature, particular attention must be paid to foundations, cross-bracing and structural stiffness, which are essential to counterbalance its vulnerability to wind forces. Although bamboo's low shear strength presents a challenge, an adequate comprehension of its properties allows for creative systems to compensate for this, and a critical focus on treatment is also non-negotiable. The material can also be prone to insect attacks and has a limited lifespan, making it important to include proactive 'preservation by design' approaches as an integral part of any bamboo-based construction.

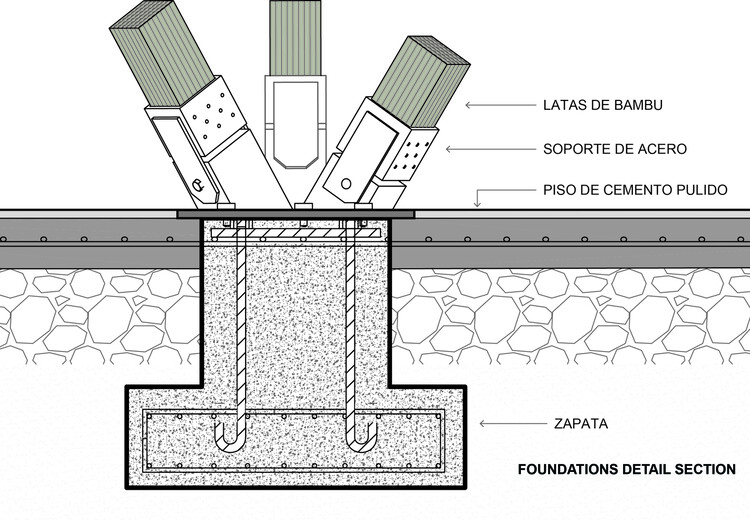

The Luum Temple embraces a balance between these advantages and challenges. The interconnected roof diaphragm, for instance, is made of cross-layers of bamboo mats —a modern nod to empirical techniques of the past that give the structure impressive resistance to lateral loads. To account for bamboo's natural flex and movement, the structure incorporates articulated foundations and a central compression ring. This approach not only captures bamboo's intrinsic strengths but also circumvents its limitations, demonstrating a model way to build sustainably and innovatively.

The Engineering Process

A defining feature of the Luum Temple project was its successful integration of up-to-date bamboo engineering concepts with a timeless architectural framework. Rather than merely following standard procedures, the engineering team ventured into new territory by developing custom methods, all while adhering to internationally recognized standards. This inventive approach adeptly navigated through Mexico's intricate regulatory framework surrounding bamboo construction and also set a solid precedent for future bamboo projects.

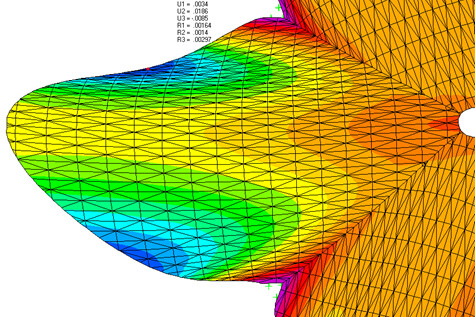

The technical workflow of the project was facilitated by a robust software toolkit. The structural design process started with AutoCAD 3D, where the structure’s geometry was modeled and compatibilized for the next steps. Following this, structural analysis was carried out using specialized structural analysis software SAP2000 v.14.

The structure was divided into three main element types to orient the design process:

- Arches , spanning in the edges of the structure and radially from the center;

- Joists , spanning in layers and connecting the main arches over several layers;

- Roof diaphragm , conformed by the rigid surface resulting from several layers of joist triangulation and split weaving below the roof.

As the project is located in a region prone to hurricane winds and seismic activities, the engineering strategy emphasized shape stiffness, triangulation, and a robust diaphragm. These elements were specifically selected to offset lateral forces that could compromise the structure. Consequently, each component in the structure was interconnected and designed to function cohesively, ensuring resilience against some of nature's most extreme forces.

In terms of load magnitudes, considerable seismic loads and 250km/h hurricane wind loads governed the design. These were combined with dead loads (weight of the structure and roofing) and live loads to obtain the design internal forces for each element of the structure. For this, the allowable stress method was employed, complying with the most adequate approach for structural bamboo design. The loads were then multiplied by the prescribed load coefficient for each of the required load combinations according to bamboo-specific structural codes. Finally, the maximum internal forces found in the most stressed arch, joist, and roof diaphragm elements were considered for the final design of the structural elements.

Equipped with structural insights, such as the internal forces acting in the structure for each load combination, the structural components were designed based on bamboo-specific building codes, such as the NSR-10 (Colombia) and the ISO 22156 (International). Specialized software like WoodWorks® Connections, SFS Timber Work, and APF Wood Joint were then employed for the design of the connecting elements between structural components.

At the uppermost part of the structure, the primary arches converge, interconnected by a central steel compression ring. This design feature ensures each arch tip converges towards a centralized point, reminiscent of a star's radiating arms. Drawing a parallel to airplane wings, which flex and bounce to a certain extent during flight to prevent structural failure, bamboo structures adopt a similar engineering principle. To ensure the bamboo components can flex and adapt during adverse events like storms or earthquakes without fracturing, the central compression ring incorporates robust hinged connections, as illustrated in the subsequent images.

In this project, a detailed analysis was undertaken to determine the mechanical connections at the base. Designed in a hinged manner, similar to the central compression ring, the connections between bamboo arches and the foundation permit rotational movement. This design strategy ensures that bamboo elements are spared from excess shear and bending forces, which aren't their strengths. Instead, the bamboo primarily experiences tension and compression forces parallel to its fibers.

As we've seen, bamboo isn't just a rapidly renewable resource —it's a structural material with the potential to change the landscape of sustainable architecture in the upcoming decades. From its historical roots to its modern-day applications, bamboo proves that when tradition meets innovation, magic happens.

Unlock the Potential of Bamboo Structures

For those serious about pioneering the next wave of green construction and understanding the practical aspects of using bamboo as a structural material, the "Bamboo Structures" eBook series can be an essential guide. This recent publication dives deep into methodologies, design details, and example applications, serving as an invaluable resource for both novices and experts in the field. Developed based on the structural calculation methods used for the Luum Temple project, this first volume addresses a long-awaited resource gap, offering a clear lens into bamboo structural design for the wider audience.

Learn more about the “Bamboo Structures” eBook here.

Image gallery

- Sustainability

世界上最受欢迎的建筑网站现已推出你的母语版本!

想浏览archdaily中国吗, you've started following your first account, did you know.

You'll now receive updates based on what you follow! Personalize your stream and start following your favorite authors, offices and users.

Mechanical Properties of Engineering Materials: Relevance in Design and Manufacturing

- In book: Introduction to Mechanical Engineering (pp.3-41)

- Mountain State University

Abstract and Figures

Discover the world's research

- 25+ million members

- 160+ million publication pages

- 2.3+ billion citations

- Rachasit Jeencham

- Nantawat Chiaoketwit

- Piya-on Numpaisal

- Stephen O. Olanrewaju

- Theophilus T. Ewetumo

- Dejana Pejak Simunec

- Adrian Trinchi

- Ahmet Yokuş

- Arinze Everest Chinweze

- Heru Sukanto

- Joko Triyono

- Poom Narongdej

- Mana Hassanpour

- Nicolas Alterman

- Ehsan Barjasteh

- S. P. (Stuart P.) Keeler

- ENG FRACT MECH

- G.R. Johnson

- Rolf E. Hummel

- R. Von Mises

- Gorton M. Goodwin

- Frederick Winslow Taylor

- Recruit researchers

- Join for free

- Login Email Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google Welcome back! Please log in. Email · Hint Tip: Most researchers use their institutional email address as their ResearchGate login Password Forgot password? Keep me logged in Log in or Continue with Google No account? Sign up

MSE 5090: Case Studies in Material Selection

Case study topics.

| Reserve desk - Wadley, H. and R. Vancheeswaran. "The Intelligent Processing of Materials: An Overview and Case Study", January, 1998. 19-30. This case study analyzes new process models and simulation tools that are used to "explore the processibility of different composite systems and identify optimum process schedules; in conjunction with microstructure sensors, they can now be used for model-based feedback control." | |

| Reserve desk - " , Getting Good Wood (or Aluminum) on the Ball", Mechanical Engineering, October, 1990. 40 - 47. This article discusses the increasing technical sophistication of the baseball bat design and material choice to produce high-performance bats. | |

| Reserve desk (student case study) - Smith, J., "Materials Selection for a Bicycle Frame", 1993. This case study explores "the suitability of 6061 aluminum, 6Al/4V titanium, graphite fiber reinforced epoxy, 4130 steel, and a SiC/Al metal matrix composite" for use in bicycle frames. | |

| Reserve desk (student case study) - Cann, M., "Material Selection for a High Performance Ice Axe", 1998. This case study is by an engineer for Black Diamond Equipment, Inc., a Salt Lake City manufacturer of climbing equipment. The goal is to "research different axe shaft materials and come to a final recommendation based on the identified functional requirements and constraints." | |

| Reserve desk - Lewis, G., A Vaulting Pole, Chapter 14, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 132 - 137. "From the viewpoint of material selection, the objective is to choose a material that has a very high value of specific endurance strength and whose use would result in the lowest values of (a) the weight of the vaulting pole, for a given "pole stiffness", and (b) the total cost of the pole (raw material plus fabrication costs). | |

| Reserve desk (student case study) - Harper, D., "Case Study: A Look inside Snowboard Construction Components", 1998. This case study "compares and contrasts an ideal case study with one performed by DNR, USA. The study involves replacing a European produced rubber component found in the tip and tail regions of the Santa Cruz freestyle snowboards with a domestically produced material with similar material properties. This study takes a material engineering approach to choosing a material and compares it to the actual steps that were taken to reach a solution." | |

| Reserve desk - Lewis, G., Skateboard Wheels, Chapter 16, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 143 - 148. This case study focuses on the selection of the materials for skateboard wheels. This is a case where the "best material" based on data is not the one used because of cost and other constraints. | |

| Reserve desk - Anderson, D. "Material Demands for ", MRS Bulletin, August, 1988. 30 - 35. In this article the author presents a cursory look at optical neural networks and focuses on architectures that employ photo refractive materials. He concludes with "we need a medium that is to neural networks what silicon is to digital computers. Optical approaches reveal their promises, and we look to materials technology advances to realize them." Does that medium now exist? | |

| Reserve desk (student case study) - Baczuk, J. and G. Gordon, "Lightweight, Dimensionally Stable, Polymer-Ceramic Composites for Space Systems & Commercial Applications", 1998. LoTEC, Inc., a Low Thermal Expansion ceramics company in SLC specializes in NZP, a material that exhibits near-zero thermal expansion . The applications for which this material has an advantage are discussed , along with constraints in manufacturing the material. | |

| Reserve desk (student case study) - Larson, R., "An Investigation into the Possibility and Feasibility of Using Thermoplastic Elastomers in Automobile Tires", 1993. This case study was motivated by the unrecyclability of tires. In addition to recyclability, thermoplastics have a simpler manufacturing process. They do have other problems, including the limitation of having the molding be reversible by heat. In the conclusion, several questions are proposed for additional research. | |

| Reserve desk (student case study) - Laramee, R., "Case Study, Thiokol Corporation, Aerospace Propulsion Nozzle Material Evaluation", 1990. "This case study relates to the engineering evaluation of downsizing by 50% the shuttle boosters to meet the propulsion requirements of the Advanced Launch Systems (ALS)." | |

| Reserve desk - Lewis, G., Sounding Board of an Orchestral Harp, Chapter 13, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 125 - 131. This case study focuses on the problem of "board creep." When the harp is tuned elastic deformation occurs. Eventually the strain may cause the sounding board to separate from the the sounding box, rendering the instrument unplayable. | |

| Reserve desk (student case study) - Lobo, S., "Design Criteria and Selection of an Optimal Blood Analogue Fluid", 1993. This case study attempts to select a fluid with "optimally-matched fluid mechanical parameters" to blood and "to recommend the standardized use of such a fluid in subsequent flow investigations of blood." | |

| Reserve desk (student case study) - Mulder, M., "Material Selection for Small Vascular Grafts", 1993. "This study was conducted in response to questions raised by a group of investors who are interested in exploring the financial incentives of investing in small diameter vascular grafts...Vascular grafts are porous polymer tubes which are used to replace natural blood vessels or reroute blood around an obstructed vessel." | |

| Reserve desk - Lewis, G., Question 53, Coatings for Human Teeth, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 399 - 402. Brief description of enamel, dentin, and cementum, and all parts of the human tooth from materials science viewpoint. Identifies material requirements for a human tooth coating. Compares performance of natural enamel with candidate materials. | |

| Reserve desk (student case study) - Pardey, H., "Replacement for Hard Chrome Surfaces in Hydraulic Cylinders", 1993. "This case study is to determine an alternate material to replace the hard chrome surfacing on diamond drill hydraulic chuck cylinders and pistons." | |

| Reserve desk (student case study) - Chandra, D., "Case study of selection of Materials for Automobile Body Panels". "In the present study selection of materials for automobile body panel is elucidated and a performance index is prepared for materials chosen." The purpose is to find "new materials which can replace high energy consuming conventional materials." | |

| Reserve desk (student case study) - Billings, E., "Electrosurgical Scalpels". In this case study, the materials restrictions for materials to be used in as electrosurgical scalpels were analyzed and used to select materials for this application." | |

| Reserve desk - Destefani, J., "Advances in Intermetallics", Advanced Materials & Processes, 2/98. 37 - 41. This article looks at the processing and properties of intermetallic compounds. Composites discussed include Ni Al, Ti Al, and NiAl. | |

| Reserve desk - Lewis, G., Flat Spiral Spring Chapter 23, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 194 - 197. "The objective is to use the spring to store energy and to recover the same either slowly or rapidly, depending on the function of the spring. Thus the flat spiral spring finds itself in applications such as clocks, watches, and gramophones, as are found in antique shops or in private bric-a-brac collections." | |

| Reserve desk - Bowman, R. and R. Noebe, "Up-and-Coming IMCs", Advanced Materials & Processing, 8/89. 35 - 40. This article discusses the development and testing of Intermetallic-matrix composites (IMCs). It also features the fabrications methods, including powder cloth, fiber/foil, arc and plasmal thermal spray. | |

| Reserve desk - Lewis, G., Pressure Capsule and Outer Hull of a Deep Sea-Operating Vehicle, Chapter 1, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 1 - 9. "The objective in flywheel design being to store the maximum amount of kinetic energy per unit mass of the flywheel, the two criteria of performance are thus stored kinetic en`ergy and flywheel mass. In analyzing for the optimum material, the discussion is limited to thin flywheels so that plane stress conditions may be assumed." | |

| Reserve desk - Jagielinski, T. "Materials for Future High Performance Magnetic Recording Heads", MRS Bulletin, March, 1990. 36 - 43. This article states that "Conventional ferrite heads will be eliminated from high performance recording systems and ...The future lies with multilayers and artificial structures in which properties can be engineered independently during the fabrication process." Eight years later, is this true? | |

| Reserve desk - "Diamond Thin Film: Hot New Material for the 90's", Design News, 4-10-89. 70 - 75. This article explores the processing and potential uses for diamond film. It suggests that "the 1990s could become the decade of the diamond." Was he right? | |

| Reserve desk - Hadden, Cdr, P., "Selection of materials for a modern warship", Royal Naval Engineering College, Manadon, Plymouth, Devon PL5 3AG. "In the design of a modern warship, operational effectiveness must be balanced against cost, reliability, and maintainability. This article illustrates the extent to which the design process affects the selection of materials employed in the construction of the latest class of anti-submarine warfare ship, the Type 23, and emphasizes the increasing extent that cost plays." | |

| Reserve desk - Lewis, G., Pressure Capsule and Outer Hull of a Deep Sea-Operating Vehicle, Chapter 10, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 96 - 103. "Both the deep submersible and the deep submergence vehicles require critical designs to obtain the optimum mix of operating depth and payload. One way of achieving such a mix is through proper selection of materials for the key structural components, the pressure capsule and the outer hull." | |

| Reserve desk - Lewis, G., Thermal Shock Resistance, Chapter 7, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 56 - 73. "Thermal shock is the phenomenon whereby a body experiences instantaneous or stepwise changes in temperature due to rapid change in either external temperature or the rate of internal heat generation. As a result of these changes, internal thermal stresses are generated that may weaken the material or, in extreme cases, lead to fracture." | |

| Reserve desk - Lewis, G., Shape Memory Effect Applications, Chapter 11, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 96 - 103. "The shape memory effect (SME) is the ability of certain alloys to 'remember' the dimensions that a basic shape (wire, rod, sheet, table) possessed at a previous point in its thermomechanical history and to work to recover those dimensions upon heating above and/or cooling below a characteristic temperature, termed the transformation temperature or temperature range." | |

| Reserve desk - Lewis, G., Receiver of a High-Temperature Solar Energy Thermal System, Chapter 24, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 198 - 201. "The receivers in SETS are the key components that determine the operating temperature at which power conversion or thermal processes can take place. The achievement of high operating temperatures (greater than 800°C.) makes possible higher-efficiency engines and an increased number of useful industrial processes. | |

| Reserve desk - Lewis, G., Drive shaft of a Medium-sized Car, Question 2, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 243 - 249. "The use of filamentary composite materials in automotive vehicle components is on the increase. (a) Demonstrate the plausibility of this statement. (b) State the attractive features of these materials for one automotive vehicle component, the drive shaft of a medium-sized car." | |

| Reserve desk (student case study) - Rudert, J. " Selection of a Material for the Walls and Ceiling of a Low-Cost Paint Booth", 1998. "This case study concerns the selection of a material for the walls and ceilings of a low-cost automotive paint booth. The constraints include maximum stiffness per unit weight, ease of assembly of the final product, toxicity of the material during processing and in case of a fire, cost. | |

| . | Reserve desk - Lewis, G., Materials for Hypervelocity Vehicles, Chapter C1, Prentice Hall, Englewood Cliffs, New Jersey, 1990. 433 - 440. "The selection of materials for use on external surfaces of hypervelocity vehicles is governed primarily by the need to protect these sections from the very high temperatures created by aerodynamic heating during flight. To keep the weight of these vehicles to the minimum possible, high-temperature-resistant but light-weight materials, rather than thermal protection shields, are preferred." |

| . | Reserve desk (student case study) - Knudsen, M., "Materials Selection and Performance in the Chemical Process Industries: Case Studies", 1998. "Case studies taken from three actual projects in differing industries where specific materials selection was required were reviewed. The Ashby method was used in each case...The Ashby system worked well for these cases." |

Engineering Databases

- Academic Complete E-books

- Academic Search Complete

- Access Engineering

- ACM Digital Library

- American Chemical Society

- Applied Science and Technology Source

- ASM Handbooks

- ASME Digital Collection

- ASTM Compass Standards

- Auto Repair Source

- AVON - Academic Video Online

- Dictionary of Natural Products

- Digital Commons

- EBSCO eBooks Collection

Engineering Case Studies

- Google Scholar

- Grammarly Premium

- IEEE Xplore

- Journal Citation Reports

- Journal List A-Z

- JSTOR Collection

- Knovel Science & Engineering Datasets

- LinkedIn Learning

- MeLCat: Music, Books, Audio & More from all over Michigan

- SAE Mobilus

- Science Direct

- Small Engine Repair Reference Center

- Springer Journals and eBooks

- Web of Science

- WorldCat: Books, DVDs, CDs & Articles from around the world

- About the Database

- Creating Persistent Links

Creating a Persistent Link:

Engineering Case Studies has an option for persistent links inside each resource.

To locate the persistent link, select the resource you wish to share. Beneath the resource, you will see an option to "embed/link":

From here, you can choose to copy the persistent link from the pop-up window:

Using Engineering Case Studies

The analysis of engineering failures is an essential part of many engineering curricula today. This focus enables modern engineers and scholars to learn what not to do and how to create designs with a greater chance of success. Key to learning is establishing the nature of each failure—structural, corrosive, electrical, etc.—and understanding that element.

The engineering field needs a comprehensive and authoritative resource to provide in-depth, impartial analysis of key engineering failures. Engineering Case Studies Online is a collection that will grow to include 250 hours of video and 50,000 pages of text resources to meet this growing need. Content is displayed alongside targeted learning objects designed to facilitate detailed understanding of the causes and impact of these failures. Materials in the collection include:

• Feature-length video documentaries of major failures.

• Monographs explaining cases in detail and describing key engineering concepts and issues.

• Simulations depicting precisely what went wrong.

• Primary footage of accidents, including related news segments.

• Audio footage and transcripts.

• Testimonies from participants, victims, and witnesses.

• Images, accident reports, blueprints, and other key archival content whenever available.

• Bibliographies of authoritative materials from newspapers, Web sites, and journals.

• Specially written cases that explore engineering ethics.

The collection provides in-depth coverage for more than 50 of the most frequently taught and seminal case studies around the world together. Example cases include:

| • Air France flight 4590 | • Comet airliners | • Space shuttle Challenger |

| • Apollo 13 | • Deepwater Horizon oil rig | • Tacoma Narrows bridge |

| • The Big Dig | • Ford Pinto | • Titanic |

| • Boeing 787 Dreamliner | • Fukushima Daiichi nuclear power plant | • TWA flight 800 |

| • Chernobyl power plant | • Hyatt Regency walkway | • Plus many more |

All materials in Engineering Case Studies Online are carefully cultivated by expert editors, with the assistance of an advisory board of engineering librarians and faculty. Materials come from a wide range of content partners, including the Digital Rights Group, BBC, Future Media, TVF International, as well as leading academic publishers such as Princeton University Press, John Wiley & Sons, Harvard University Press, and engineering associations such as the American Society of Civil Engineers.

More than 60 percent of video material in the collection was produced since 2000, and new content is added regularly. The database is global in focus, and originates from the United States, the United Kingdom, and Australia, with selections from across Europe and Asia. And because Engineering Case Studies Online addresses cases from a variety of angles, including their legal and ethical implications, the collection has broad applications for fields including architecture, business, law, urban planning, health and safety, environmental studies, science, sociology, media, and technology.

- Last Updated: Sep 3, 2024 3:38 PM

- URL: https://libguides.kettering.edu/EngineeringDatabases

|

|

|

- Products & Services

- Engineering News

- Standards Library

- Reference Library

I forgot my password.

Don't have an account?

6.1 Introduction and Synopsis

Here we have a collection of case studies illustrating the screening methods of Chapter 5. They are deliberately simplified to avoid obscuring the method under layers of detail. In most cases little is lost by this: the best choice of material for the simple example is the same as that for the more complex, for the reasons given in Chapter 5. More realistic case studies are developed in later chapters.

Each case study is laid out in the same way:

the problem statement, setting the scene,

the model, identifying function, constraints, objectives, and free variables, from which emerge the attribute limits and material indices,

the selection in which the full menu of materials is reduced by screening and ranking to a short-list of viable candidates,

the postscript, allowing a commentary on results and philosophy.

Techniques for seeking supporting information are left to later chapters.

The first few examples are simple but illustrate the method well. Later examples are less obvious and require clear thinking to identify and distinguish objectives and constraints. Confusion here can lead to bizarre and misleading conclusions. Always apply common sense: does the selection include the traditional materials used for that application? Are some members of the subset obviously unsuitable? If they are, it is usually because a constraint has been overlooked: it must be formulated and applied.

Most of the case studies use the hard-copy charts of Chapter 4; Sections 6.17 and 6.18 illustrate the use of computer-based...

UNLIMITED FREE ACCESS TO THE WORLD'S BEST IDEAS

SIGN UP TO SEE MORE

GlobalSpec collects only the personal information you have entered above, your device information, and location data. GlobalSpec may share your personal information and website activity with our clients for which you express explicit interest, or with vendors looking to reach people like you. GlobalSpec will retain this data until you change or delete it, which you may do at any time.

Contact Preferences

By submitting your registration, you agree to our Privacy Policy .

This is embarrasing...

An error occurred while processing the form. Please try again in a few minutes.

Customize Your GlobalSpec Experience

Select your free newsletters, industry newsletters, select your free product alerts.

Breadcrumbs Section. Click here to navigate to respective pages.

Forensic Materials Engineering

DOI link for Forensic Materials Engineering

Get Citation

Most books on forensic engineering focus on civil engineering failures rather than consumer or general mechanical products. Unique both in scope and style, this treatment is built upon case studies of real accidents, broadly focused on consumer products, and dedicated to problem solving through scientific principles. Each well-illustrated case stud

TABLE OF CONTENTS

Chapter 1 | 24 pages, introduction, chapter 2 | 36 pages, materials in distress, chapter 3 | 24 pages, establishing the load transfer path, chapter 4 | 46 pages, a "toolbox" for forensic engineers, chapter 5 | 40 pages, failure due to manufacturing faults, chapter 6 | 44 pages, fluid transport, chapter 7 | 40 pages, failure of storage vessels, chapter 8 | 32 pages, accidents in the workplace, chapter 9 | 32 pages, failure of medical implements, chapter 10 | 30 pages, component failure in road traffic accidents, chapter 11 | 16 pages, fraudulent insurance claims, chapter 12 | 14 pages, criminal cases, chapter 13 | 50 pages, intellectual property cases.

- Privacy Policy

- Terms & Conditions

- Cookie Policy

- Taylor & Francis Online

- Taylor & Francis Group

- Students/Researchers

- Librarians/Institutions

Connect with us

Registered in England & Wales No. 3099067 5 Howick Place | London | SW1P 1WG © 2024 Informa UK Limited

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

Additive manufacturing of metal materials for construction engineering: an overview on technologies and applications.

1. Introduction

2. metal additive manufacturing technologies, 2.1. materials, 2.2. overview remarks, 2.3. features of 3d printing methods, 3. printing process parameters for metal am, 3.1. laser-related parameters, 3.2. scan-related parameters, 3.3. powder-related parameters, 3.4. temperature-related parameters, 3.5. printing directions and orientations, 3.6. effects of process parameters on the properties of 3d-printed metals, 4. metal additive manufacturing in construction, 4.1. optimized structural node by arup, 4.2. mx3d pedestrian bridge, 4.3. takenaka connector, 4.4. am steel reinforcement for concrete, 4.5. joining aluminium profiles, 4.6. future applications, 5. the potentials of metal am in topological optimization, 5.1. nonconventional geometries, 5.1.1. topology optimization.

Click here to enlarge figure

- SIMP method

- Level-Set method

- The application of topological optimization

5.1.2. Lightweight Components

5.2. use of am in repair of existing structures.

- Preparation stage. In the first step, considerations concern the cost-effectiveness of the repair/reinforcement of the degraded component. Next, a geometric check is performed between the worn elements and the nominal model. This comparison generates an error map, which highlights the errors between the two models. Finally, the repair area can be identified and judgements made on the extent of the damage.

- Production stage. In this stage, the previously identified area is repaired/reinforced through AM or hybrid manufacturing processes.

- Post-repair stage. In the final step, a geometric inspection is performed to verify the correct execution. In addition, the restored element can be mechanically characterised by means of material strength tests.

6. Conclusions

Author contributions, data availability statement, conflicts of interest.

- Xiang, H.; Zhou, Y.; Zhang, X.; Li, J.; Huang, Y.; Mou, G.; Wu, C. Supportfree Printing in Laser Powder Bed Fusion: Formation Mechanisms of Discontinuity, Dross and Surface Roughness. Opt. Laser Technol. 2024 , 177 , 111201. [ Google Scholar ] [ CrossRef ]

- Housholder, R.F. Molding Process. U.S. Patent 4247508, 27 January 1981. [ Google Scholar ]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012 , 2012 , 208760. [ Google Scholar ] [ CrossRef ]

- Chen, L.-Y.; Qin, P.; Zhang, L.; Zhang, L.-C. An Overview of Additively Manufactured Metal Matrix Composites: Preparation, Performance, and Challenge. Int. J. Extrem. Manuf. 2024 , 6 , 052006. [ Google Scholar ] [ CrossRef ]

- Coon, C.; Pretzel, B.; Lomax, T.; Strlič, M. Preserving Rapid Prototypes: A Review. Herit. Sci. 2016 , 4 , 40. [ Google Scholar ] [ CrossRef ]

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019 , 11 , 1–27. [ Google Scholar ] [ CrossRef ]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.K.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder Bed Fusion Process in Additive Manufacturing: An Overview. Mater. Today Proc. 2019 , 26 , 3058–3070. [ Google Scholar ] [ CrossRef ]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017 , 117 , 10212–10290. [ Google Scholar ] [ CrossRef ]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016 , 117 , 371–392. [ Google Scholar ] [ CrossRef ]

- Bhatia, A.; Sehgal, A.K. Additive Manufacturing Materials, Methods and Applications: A Review. Mater. Today Proc. 2021 , 81 , 1060–1067. [ Google Scholar ] [ CrossRef ]

- Pratheesh Kumar, S.; Elangovan, S.; Mohanraj, R.; Ramakrishna, J.R. Review on the Evolution and Technology of State-of-the-Art Metal Additive Manufacturing Processes. Mater. Today Proc. 2021 , 46 , 7907–7920. [ Google Scholar ] [ CrossRef ]

- Wang, Y.; Zhou, Y.; Lin, L.; Corker, J.; Fan, M. Overview of 3D Additive Manufacturing (AM) and Corresponding AM Composites. Compos. Part A Appl. Sci. Manuf. 2020 , 139 , 106114. [ Google Scholar ] [ CrossRef ]

- Fijoł, N.; Aguilar-Sánchez, A.; Mathew, A.P. 3D-Printable Biopolymer-Based Materials for Water Treatment: A Review. Chem. Eng. J. 2022 , 430 , 132964. [ Google Scholar ] [ CrossRef ]

- Jiang, J.; Xu, X.; Stringer, J. Support Structures for Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2018 , 2 , 64. [ Google Scholar ] [ CrossRef ]

- Karar, G.C.; Kumar, R.; Chattopadhyaya, S. An Analysis on the Advanced Research in Additive Manufacturing. In Advances in Production and Industrial Engineering. Part of the Lecture Notes in Mechanical Engineering Book Series ; Springer: Singapore, 2021; pp. 229–277. ISBN 9789811555183. [ Google Scholar ]

- ISO/ASTM 52900 ; Additive Manufacturing—General Principles—Terminology. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- Durai Murugan, P.; Vijayananth, S.; Natarajan, M.P.; Jayabalakrishnan, D.; Arul, K.; Jayaseelan, V.; Elanchezhian, J. A Current State of Metal Additive Manufacturing Methods: A Review. Mater. Today Proc. 2021 , 59 , 1277–1283. [ Google Scholar ] [ CrossRef ]

- Shrinivas Mahale, R.; Shamanth, V.; Hemanth, K.; Nithin, S.K.; Sharath, P.C.; Shashanka, R.; Patil, A.; Shetty, D. Processes and Applications of Metal Additive Manufacturing. Mater. Today Proc. 2021 , 54 , 228–233. [ Google Scholar ] [ CrossRef ]

- Badoniya, P.; Srivastava, M.; Jain, P.K.; Rathee, S. A State-of-the-Art Review on Metal Additive Manufacturing: Milestones, Trends, Challenges and Perspectives ; Springer: Berlin/Heidelberg, Germany, 2024; Volume 46, ISBN 0123456789. [ Google Scholar ]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017 , 7 , 120–133. [ Google Scholar ] [ CrossRef ]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018 , 143 , 172–196. [ Google Scholar ] [ CrossRef ]

- Wang, J.C.; Dommati, H.; Hsieh, S.J. Review of Additive Manufacturing Methods for High-Performance Ceramic Materials. Int. J. Adv. Manuf. Technol. 2019 , 103 , 2627–2647. [ Google Scholar ] [ CrossRef ]

- Wang, Y.; Chen, R.; Liu, Y. A Double Mask Projection Exposure Method for Stereolithography. Sens. Actuators A Phys. 2020 , 314 , 112228. [ Google Scholar ] [ CrossRef ]

- Mazzoli, A. Selective Laser Sintering in Biomedical Engineering. Med. Biol. Eng. Comput. 2013 , 51 , 245–256. [ Google Scholar ] [ CrossRef ]

- Redwood, B.; Schoffer, F.; Garret, B. The 3D Printing Handbook. Technologies, Design and Applications ; 3D Hubs B.V.: Amsterdam, The Netherlands, 2020. [ Google Scholar ]

- Giri, J.; Sunheriya, N.; Sathish, T.; Kadu, Y.; Chadge, R.; Giri, P.; Parthiban, A.; Mahatme, C. Optimization of Process Parameters to Improve Mechanical Properties of Fused Deposition Method Using Taguchi Method. Interactions 2024 , 245 , 87. [ Google Scholar ] [ CrossRef ]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017 , 10 , 791–803. [ Google Scholar ] [ CrossRef ]

- Hafsa, M.N.; Kassim, N.; Ismail, S.; Kamaruddin, S.A.; Hafeez, T.M.; Ibrahim, M.; Samsudin, Z.H. Study on Surface Roughness Quality of FDM and MJM Additive Manufacturing Model for Implementation as Investment Casting Sacrificial Pattern. J. Mech. Eng. 2018 , 5 , 25–34. [ Google Scholar ]

- Emiliani, N.; Porcaro, R.; Pisaneschi, G.; Bortolani, B.; Ferretti, F.; Fontana, F.; Campana, G.; Fiorini, M.; Marcelli, E.; Cercenelli, L. Post-Printing Processing and Aging Effects on Polyjet Materials Intended for the Fabrication of Advanced Surgical Simulators. J. Mech. Behav. Biomed. Mater. 2024 , 156 , 106598. [ Google Scholar ] [ CrossRef ]

- Yang, Y.; Bharech, S.; Finger, N.; Zhou, X.; Schröder, J.; Xu, B.X. Elasto-Plastic Residual Stress Analysis of Selective Laser Sintered Porous Materials Based on 3D-Multilayer Thermo-Structural Phase-Field Simulations. npj Comput. Mater. 2024 , 10 , 117. [ Google Scholar ] [ CrossRef ]

- Rajesh, R.; Sudheer, S.; Kulkarni, M.V. Selective Laser Sintering Process—A Review. Int. J. Curr. Eng. Sci. Res. (IJCESR) 2015 , 2 , 91–100. [ Google Scholar ]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive Manufacturing in Construction: A Review on Processes, Applications, and Digital Planning Methods. Addit. Manuf. 2019 , 30 , 100894. [ Google Scholar ] [ CrossRef ]

- Volpe, S.; Sangiorgio, V.; Fiorito, F.; Varum, H. Overview of 3D Construction Printing and Future Perspectives: A Review of Technology, Companies and Research Progression. Archit. Sci. Rev. 2022 , 67 , 1–22. [ Google Scholar ] [ CrossRef ]

- Placzek, G.; Schwerdtner, P. Concrete Additive Manufacturing in Construction: Integration Based on Component-Related Fabrication Strategies. Buildings 2023 , 13 , 1769. [ Google Scholar ] [ CrossRef ]

- Pacillo, G.A.; Ranocchiai, G.; Loccarini, F.; Fagone, M. Additive Manufacturing in Construction: A Review on Technologies, Processes, Materials, and Their Applications of 3D and 4D Printing. Mater. Des. Process. Commun. 2021 , 3 , e253. [ Google Scholar ] [ CrossRef ]

- Scheel, P.; Wrobel, R.; Rheingans, B.; Mayer, T.; Leinenbach, C.; Mazza, E.; Hosseini, E. Advancing Efficiency and Reliability in Thermal Analysis of Laser Powder-Bed Fusion. Int. J. Mech. Sci. 2023 , 260 , 108583. [ Google Scholar ] [ CrossRef ]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015 , 2 , 041101. [ Google Scholar ] [ CrossRef ]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Liu, J.; Shi, Y. Differences in Microstructure and Properties between Selective Laser Melting and Traditional Manufacturing for Fabrication of Metal Parts: A Review. Front. Mech. Eng. 2015 , 10 , 111–125. [ Google Scholar ] [ CrossRef ]

- Du, X.; Chen, J.; She, Y.; Liu, Y.; Yang, Y.; Yang, J.; Dong, S. Effect of Process Parameter Optimization on Morphology and Mechanical Properties of Ti 6 Al 4 V Alloy Produced by Selective Laser Melting. Prog. Nat. Sci. Mater. Int. 2023 , 33 , 911–917. [ Google Scholar ] [ CrossRef ]

- Fette, M.; Sander, P.; Wulfsberg, J.; Zierk, H.; Herrmann, A.; Stoess, N. Optimized and Cost-Efficient Compression Molds Manufactured by Selective Laser Melting for the Production of Thermoset Fiber Reinforced Plastic Aircraft Components. Procedia CIRP 2015 , 35 , 25–30. [ Google Scholar ] [ CrossRef ]

- Liu, B.; Bai, P.; Li, Y. Post Treatment Process and Selective Laser Sintering Mechanism of Polymer-Coated Mo Powder. Open Mater. Sci. J. 2011 , 5 , 194–198. [ Google Scholar ] [ CrossRef ]

- Andreacola, F.R.; Capasso, I.; Pilotti, L.; Brando, G. Influence of 3D-Printing Parameters on the Mechanical Properties of 17-4PH Stainless Steel Produced through Selective Laser Melting. Frat. Intregrità Strutt. 2021 , 58 , 282–295. [ Google Scholar ] [ CrossRef ]

- Andreacola, F.R.; Capasso, I.; Langella, A.; Brando, G. 3D-Printed Metals: Process Parameters Effects on Mechanical Properties of 17-4PH Stainless Steel. Heliyon 2023 , 9 , e17698. [ Google Scholar ] [ CrossRef ]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting-Selection Guidelines. Materials 2017 , 10 , 672. [ Google Scholar ] [ CrossRef ]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012 , 28 , 167–177. [ Google Scholar ] [ CrossRef ]

- Huang, N.; Cook, O.J.; Argüelles, A.P.; Beese, A.M. Review of Process–Structure–Property Relationships in Metals Fabricated Using Binder Jet Additive Manufacturing. Metallogr. Microstruct. Anal. 2023 , 12 , 883–905. [ Google Scholar ] [ CrossRef ]

- Tischel, F.; Reineke, L.; Alrashdan, J.; Ploshikhin, V. Experimental Investigation and Modeling of Densification during Sintering of Binder Jetted Ti–6Al–4V. Powder Technol. 2024 , 444 , 119958. [ Google Scholar ] [ CrossRef ]

- Aramian, A.; Razavi, S.M.J.; Sadeghian, Z.; Berto, F. A Review of Additive Manufacturing of Cermets. Addit. Manuf. 2020 , 33 , 101130. [ Google Scholar ] [ CrossRef ]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder Jet 3D Printing-Process Parameters, Materials, Properties, Modeling, and Challenges. Prog. Mater. Sci. 2021 , 119 , 100707. [ Google Scholar ] [ CrossRef ]

- Blunk, H.; Seibel, A. Design Guidelines for Metal Binder Jetting. Prog. Addit. Manuf. 2024 , 9 , 725–732. [ Google Scholar ] [ CrossRef ]

- Dwivedi, S.; Dixit, A.R.; Das, A.K.; Nag, A. A Novel Additive Texturing of Stainless Steel 316L Through Binder Jetting Additive Manufacturing. Int. J. Precis. Eng. Manuf. Green Technol. 2023 , 10 , 1605–1613. [ Google Scholar ] [ CrossRef ]

- Mueller, B.; Kochan, D. Laminated Object Manufacturing for Rapid Tooling and Patternmaking in Foundry Industry. Comput. Ind. 1999 , 39 , 47–53. [ Google Scholar ] [ CrossRef ]

- Kan, C.; Zhao, L.; Cao, Y.; Ma, C.; Peng, Y.; Tian, Z. Microstructure Evolution and Strengthening Behavior of Maraging Steel Fabricated by Wire Arc Additive Manufacturing at Different Heat Treatment Processes. Mater. Sci. Eng. A 2024 , 909 , 146804. [ Google Scholar ] [ CrossRef ]

- Srivastava, M.; Rathee, S.; Tiwari, A.; Dongre, M. Wire Arc Additive Manufacturing of Metals: A Review on Processes, Materials and Their Behaviour. Mater. Chem. Phys. 2023 , 294 , 126988. [ Google Scholar ] [ CrossRef ]

- Ahmed, N. Direct Metal Fabrication in Rapid Prototyping: A Review. J. Manuf. Process. 2019 , 42 , 167–191. [ Google Scholar ] [ CrossRef ]

- Alami, A.H.; Ghani Olabi, A.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive Manufacturing in the Aerospace and Automotive Industries: Recent Trends and Role in Achieving Sustainable Development Goals. Ain Shams Eng. J. 2023 , 14 , 102516. [ Google Scholar ] [ CrossRef ]

- Arrizubieta, J.I.; Martínez, S.; Lamikiz, A.; Ukar, E.; Arntz, K.; Klocke, F. Instantaneous Powder Flux Regulation System for Laser Metal Deposition. J. Manuf. Process. 2017 , 29 , 242–251. [ Google Scholar ] [ CrossRef ]

- Pirch, N.; Linnenbrink, S.; Gasser, A.; Schleifenbaum, H. Laser-Aided Directed Energy Deposition of Metal Powder along Edges. Int. J. Heat Mass Transf. 2019 , 143 , 118464. [ Google Scholar ] [ CrossRef ]

- Yilmaz, O.; Ugla, A.A. Shaped Metal Deposition Technique in Additive Manufacturing: A Review. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016 , 230 , 1781–1798. [ Google Scholar ] [ CrossRef ]

- Agelet de Saracibar, C.; Lundbäck, A.; Chiumenti, M.; Cervera, M. Shaped Metal Deposition Processes. In Encyclopedia of Thermal Stresses ; Springer: Dordrecht, The Netherlands, 2014; pp. 4346–4355. [ Google Scholar ] [ CrossRef ]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal Additive Manufacturing: Technology, Metallurgy and Modelling. J. Manuf. Process. 2020 , 57 , 978–1003. [ Google Scholar ] [ CrossRef ]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv. Eng. Mater. 2018 , 20 , 1700952. [ Google Scholar ] [ CrossRef ]

- Li, Y.; Liang, X.; Yu, Y.; Wang, D.; Lin, F. Review on Additive Manufacturing of Single-Crystal Nickel-Based Superalloys. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022 , 1 , 100019. [ Google Scholar ] [ CrossRef ]

- Mostafaei, A.; Ghiaasiaan, R.; Ho, I.T.; Strayer, S.; Chang, K.C.; Shamsaei, N.; Shao, S.; Paul, S.; Yeh, A.C.; Tin, S.; et al. Additive Manufacturing of Nickel-Based Superalloys: A State-of-the-Art Review on Process-Structure-Defect-Property Relationship. Prog. Mater. Sci. 2023 , 136 , 101108. [ Google Scholar ] [ CrossRef ]

- Mazzucato, F.; Forni, D.; Valente, A.; Cadoni, E. Laser Metal Deposition of Inconel 718 Alloy and As-Built Mechanical Properties Compared to Casting. Materials 2021 , 14 , 437. [ Google Scholar ] [ CrossRef ]

- Dixit, S.; Liu, S. Laser Additive Manufacturing of High-Strength Aluminum Alloys: Challenges and Strategies. J. Manuf. Mater. Process. 2022 , 6 , 156. [ Google Scholar ] [ CrossRef ]

- Rometsch, P.A.; Zhu, Y.; Wu, X.; Huang, A. Review of High-Strength Aluminium Alloys for Additive Manufacturing by Laser Powder Bed Fusion. Mater. Des. 2022 , 219 , 110779. [ Google Scholar ] [ CrossRef ]

- Farber, E.; Zhu, J.N.; Popovich, A.; Popovich, V. A Review of NiTi Shape Memory Alloy as a Smart Material Produced by Additive Manufacturing. Mater. Today Proc. 2019 , 30 , 761–767. [ Google Scholar ] [ CrossRef ]

- Felice, I.O.; Shen, J.; Barragan, A.F.C.; Moura, I.A.B.; Li, B.; Wang, B.; Khodaverdi, H.; Mohri, M.; Schell, N.; Ghafoori, E.; et al. Wire and Arc Additive Manufacturing of Fe-Based Shape Memory Alloys: Microstructure, Mechanical and Functional Behavior. Mater. Des. 2023 , 231 , 112004. [ Google Scholar ] [ CrossRef ]

- Wei, S.; Zhang, J.; Zhang, L.; Zhang, Y.; Song, B.; Wang, X.; Fan, J.; Liu, Q.; Shi, Y. Laser Powder Bed Fusion Additive Manufacturing of NiTi Shape Memory Alloys: A Review. Int. J. Extrem. Manuf. 2023 , 5 , 032001. [ Google Scholar ] [ CrossRef ]

- Ostovari Moghaddam, A.; Shaburova, N.A.; Samodurova, M.N.; Abdollahzadeh, A.; Trofimov, E.A. Additive Manufacturing of High Entropy Alloys: A Practical Review. J. Mater. Sci. Technol. 2021 , 77 , 131–162. [ Google Scholar ] [ CrossRef ]

- Ron, T.; Shirizly, A.; Aghion, E. Additive Manufacturing Technologies of High Entropy Alloys (HEA): Review and Prospects. Materials 2023 , 16 , 2454. [ Google Scholar ] [ CrossRef ]

- Cao, L.; Li, J.; Hu, J.; Liu, H.; Wu, Y.; Zhou, Q. Optimization of Surface Roughness and Dimensional Accuracy in LPBF Additive Manufacturing. Opt. Laser Technol. 2021 , 142 , 107246. [ Google Scholar ] [ CrossRef ]

- Nandhakumar, R.; Venkatesan, K. A Process Parameters Review on Selective Laser Melting-Based Additive Manufacturing of Single and Multi-Material: Microstructure, Physical Properties, Tribological, and Surface Roughness ; Elsevier Ltd.: Amsterdam, The Netherlands, 2023; Volume 35, ISBN 5465151392629. [ Google Scholar ]

- Xia, C.; Pan, Z.; Polden, J.; Li, H.; Xu, Y.; Chen, S. Modelling and Prediction of Surface Roughness in Wire Arc Additive Manufacturing Using Machine Learning. J. Intell. Manuf. 2022 , 33 , 1467–1482. [ Google Scholar ] [ CrossRef ]

- Obilanade, D.; Dordlofva, C.; Törlind, P. Surface Roughness Considerations in Design for Additive Manufacturing—A Literature Review. Proc. Des. Soc. 2021 , 1 , 2841–2850. [ Google Scholar ] [ CrossRef ]

- Zai, L.; Zhang, C.; Wang, Y.; Guo, W.; Wellmann, D.; Tong, X.; Tian, Y. Laser Powder Bed Fusion of Precipitation-Hardened Martensitic Stainless Steels: A Review. Metals 2020 , 10 , 255. [ Google Scholar ] [ CrossRef ]

- Sefene, E.M. State-of-the-Art of Selective Laser Melting Process: A Comprehensive Review. J. Manuf. Syst. 2022 , 63 , 250–274. [ Google Scholar ] [ CrossRef ]

- Gardner, L.; Kyvelou, P.; Herbert, G.; Buchanan, C. Testing and Initial Verification of the World’s First Metal 3D Printed Bridge. J. Constr. Steel Res. 2020 , 172 , 106233. [ Google Scholar ] [ CrossRef ]

- Anant Pidge, P.; Kumar, H. Additive Manufacturing: A Review on 3 D Printing of Metals and Study of Residual Stress, Buckling Load Capacity of Strut Members. Mater. Today Proc. 2020 , 21 , 1689–1694. [ Google Scholar ] [ CrossRef ]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An Overview of Powder Granulometry on Feedstock and Part Performance in the Selective Laser Melting Process. Addit. Manuf. 2017 , 18 , 228–255. [ Google Scholar ] [ CrossRef ]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of Energy Density and Scanning Strategy on Densification, Microstructure and Mechanical Properties of 316L Stainless Steel Processed via Selective Laser Melting. Mater. Sci. Eng. A 2020 , 770 , 138455. [ Google Scholar ] [ CrossRef ]

- Chen, J.; Wang, X.; Pan, Y. Influence of Laser Power and Scan Speed on the Microstructure and Properties of GH4169 Alloy Prepared by Selective Laser Melting. IOP Conf. Series Mater. Sci. Eng. 2019 , 688 , 033064. [ Google Scholar ] [ CrossRef ]

- Bremen, S.; Meiners, W.; Diatlov, A. Selective Laser Melting: A Manufacturing Technology for the Future? Laser Tech J 2012 , 9 , 33–38. [ Google Scholar ] [ CrossRef ]

- Mercelis, P.; Kruth, J.P. Residual Stresses in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyp. J 2006 , 12 , 254–265. [ Google Scholar ] [ CrossRef ]

- Zhang, W.; Tong, M.; Harrison, N.M. Scanning Strategies Effect on Temperature, Residual Stress and Deformation by Multi-Laser Beam Powder Bed Fusion Manufacturing. Addit. Manuf. 2020 , 36 , 101507. [ Google Scholar ] [ CrossRef ]

- Miao, X.; Liu, X.; Lu, P.; Han, J.; Duan, W.; Wu, M. Influence of Scanning Strategy on the Performances of GO-Reinforced Ti 6 Al 4 V Nanocomposites Manufactured by SLM. Metals 2020 , 10 , 1379. [ Google Scholar ] [ CrossRef ]

- Haferkamp, L.; Haudenschild, L.; Spierings, A.; Wegener, K.; Riener, K.; Ziegelmeier, S.; Leichtfried, G.J. The Influence of Particle Shape, Powder Flowability, and Powder Layer Density on Part Density in Laser Powder Bed Fusion. Metals 2021 , 11 , 418. [ Google Scholar ] [ CrossRef ]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the Particle Size Distribution on Surface Quality and Mechanical Properties in Additive Manufactured Stainless Steel Parts. Rapid Prototyp. J. 2010 , 17 , 195–202. [ Google Scholar ] [ CrossRef ]

- Huck-Jones, D.; Langley, C. Beyond Particle Size: Exploring the Influence of Particle Shape on Metal Powder Performance. Met. Addit. Manuf. 2017 , 3 , 99–103. [ Google Scholar ]

- Eddine, S.; Letenneur, M.; Alex, C.; Brailovski, V. Influence of Particle Morphology and Size Distribution on the Powder Flowability and Laser Powder Bed Fusion Manufacturability of Ti-6Al-4V Alloy. Addit. Manuf. 2020 , 31 , 100929. [ Google Scholar ] [ CrossRef ]

- Irrinki, H.; Dexter, M.; Barmore, B.; Enneti, R.; Pasebani, S.; Badwe, S.; Stitzel, J.; Malhotra, R.; Atre, S.V. Effects of Powder Attributes and Laser Powder Bed Fusion (L-PBF) Process Conditions on the Densification and Mechanical Properties of 17-4 PH Stainless Steel. JOM J. Miner. Met. Mater. Soc. 2016 , 68 , 860–868. [ Google Scholar ] [ CrossRef ]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rahman Rashid, R.A.; Brandt, M. Effect of Scan Strategy on Density and Metallurgical Properties of 17-4PH Parts Printed by Selective Laser Melting (SLM). J. Mater. Process. Technol. 2017 , 249 , 502–511. [ Google Scholar ] [ CrossRef ]

- Nguyen, Q.B.; Luu, D.N.; Nai, S.M.L.; Zhu, Z.; Chen, Z.; Wei, J. The Role of Powder Layer Thickness on the Quality of SLM Printed Parts. Arch. Civ. Mech. Eng. 2018 , 18 , 948–955. [ Google Scholar ] [ CrossRef ]

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive Manufacturing of Steels: A Review of Achievements and Challenges. J. Mater. Sci. 2021 , 56 , 64–107. [ Google Scholar ] [ CrossRef ]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the Build Orientation on the Mechanical Properties and Fracture Modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014 , 616 , 1–11. [ Google Scholar ] [ CrossRef ]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of Processing Parameters on Tensile Properties of Selective Laser Melted 304 Stainless Steel. Mater. Des. 2013 , 50 , 581–586. [ Google Scholar ] [ CrossRef ]

- How Does Part Orientation Affect a 3D Print? Practical Design Tips for Additive Manufacturing. 2024. Available online: https://www.hubs.com/knowledge-base/how-does-part-orientation-affect-3d-print/ (accessed on 7 June 2024).

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of Building Orientation and Heat Treatment on Fatigue Behavior of Selective Laser Melted 17-4 PH Stainless Steel. Int. J. Fatigue 2017 , 94 , 218–235. [ Google Scholar ] [ CrossRef ]

- Hitzler, L.; Janousch, C.; Schanz, J.; Merkel, M.; Heine, B.; Mack, F.; Hall, W.; Öchsner, A. Direction and Location Dependency of Selective Laser Melted AlSi10Mg Specimens. J. Mater. Process. Technol. 2017 , 243 , 48–61. [ Google Scholar ] [ CrossRef ]

- Wang, C.G.; Zhu, J.X.; Wang, G.W.; Qin, Y.; Sun, M.Y.; Yang, J.L.; Shen, X.F.; Huang, S.K. Effect of Building Orientation and Heat Treatment on the Anisotropic Tensile Properties of AlSi 10 Mg Fabricated by Selective Laser Melting. J. Alloys Compd. 2022 , 895 , 162665. [ Google Scholar ] [ CrossRef ]

- Sufiiarov, V.S.; Popovich, A.A.; Borisov, E.V.; Polozov, I.A.; Masaylo, D.V.; Orlov, A.V. The Effect of Layer Thickness at Selective Laser Melting. Procedia Eng. 2017 , 174 , 126–134. [ Google Scholar ] [ CrossRef ]

- Wan, H.Y.; Zhou, Z.J.; Li, C.P.; Chen, G.F.; Zhang, G.P. Effect of Scanning Strategy on Mechanical Properties of Selective Laser Melted Inconel 718. Mater. Sci. Eng. A 2019 , 753 , 42–48. [ Google Scholar ] [ CrossRef ]

- Giganto, S.; Zapico, P.; Castro-Sastre, M.Á.; Martínez-Pellitero, S.; Leo, P.; Perulli, P. Influence of the Scanning Strategy Parameters upon the Quality of the SLM Parts. Procedia Manuf. 2019 , 41 , 698–705. [ Google Scholar ] [ CrossRef ]

- Forni, D.; Mazzucato, F.; Valente, A.; Cadoni, E. High Strain-Rate Behaviour of as-Cast and as-Build Inconel 718 Alloys at Elevated Temperatures. Mech. Mater. 2021 , 159 , 103859. [ Google Scholar ] [ CrossRef ]

- Brando, G.; Andreacola, F.R.; Capasso, I.; Forni, D.; Cadoni, E. Strain-Rate Response of 3D Printed 17-4PH Stainless Steel Manufactured via Selective Laser Melting. Constr. Build. Mater. 2023 , 409 , 133971. [ Google Scholar ] [ CrossRef ]

- Michla, J.R.J.; Nagarajan, R.; Krishnasamy, S.; Siengchin, S.; Ismail, S.O.; Prabhu, T.R. Conventional and Additively Manufactured Stainless Steels: A Review. Trans. Indian Inst. Met. 2021 , 74 , 1261–1278. [ Google Scholar ] [ CrossRef ]

- Zhu, H.H.; Lu, L.; Fuh, J.Y.H. Study on Shrinkage Behaviour of Direct Laser Sintering Metallic Powder. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2006 , 220 , 183–190. [ Google Scholar ] [ CrossRef ]

- Ramos, D.; Belblidia, F.; Sienz, J. New Scanning Strategy to Reduce Warpage in Additive Manufacturing. Addit. Manuf. 2019 , 28 , 554–564. [ Google Scholar ] [ CrossRef ]

- Enneti, R.K.; Morgan, R.; Atre, S.V. Effect of Process Parameters on the Selective Laser Melting (SLM) of Tungsten. Int. J. Refract. Met. Hard. Mater. 2018 , 71 , 315–319. [ Google Scholar ] [ CrossRef ]

- Klocke, F.; Wagner, C. Coalescence Behaviour of Two Metallic Particles as Base Mechanism of Selective Laser Sintering. CIRP Ann. 2003 , 52 , 117–180. [ Google Scholar ] [ CrossRef ]

- Simchi, A.; Pohl, H. Effects of Laser Sintering Processing Parameters on the Microstructure and Densification of Iron Powder. Mater. Sci. Eng. A 2003 , 359 , 119–128. [ Google Scholar ] [ CrossRef ]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017 , 60 , 677–688. [ Google Scholar ] [ CrossRef ]

- Ali, M.H.; Issayev, G.; Shehab, E.; Sarfraz, S. A Critical Review of 3D Printing and Digital Manufacturing in Construction Engineering. Rapid Prototyp. J. 2022 , 28 , 1312–1324. [ Google Scholar ] [ CrossRef ]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and Its Impact on the Labor Market. Sustainability 2020 , 12 , 8492. [ Google Scholar ] [ CrossRef ]

- Buchanan, C.; Gardner, L. Metal 3D Printing in Construction: A Review of Methods, Research, Applications, Opportunities and Challenges. Eng. Struct. 2019 , 180 , 332–348. [ Google Scholar ] [ CrossRef ]

- Riegger, F.; Wenzler, D.L.; Zaeh, M.F. Stud and Wire Arc Additive Manufacturing—Development of a Combined Process for the High-Productivity Additive Manufacturing of Large-Scale Lattice Structures. J. Adv. Join. Process. 2024 , 9 , 100189. [ Google Scholar ] [ CrossRef ]

- Ren, S.; Galjaard, S. ; Arup Topology Optimisation for Steel Structural Design with Additive Manufacturing. Modelling Behaviour ; Springer: Cham, Swizterland, 2015. [ Google Scholar ] [ CrossRef ]

- Galjaard, S.; Hofman, S.; Ren, S. Optimizing Structural Building Elements in Metal by Using Additive Manufacturing. Proc. Int. Assoc. Shell Spat. Struct. 2015 , 2 , 1–12. [ Google Scholar ]

- Galjaard, S.; Hofman, S.; Ren, S. New Opportunities to Optimize Structural Designs in Metal by Using Additive Manufacturing. In Advances in Architectural Geometry 2014 ; Springer: Cham, Swizterland, 2015. [ Google Scholar ] [ CrossRef ]

- Gardner, L. Metal Additive Manufacturing in Structural Engineering—Review, Advances, Opportunities and Outlook. Structures 2023 , 47 , 2178–2193. [ Google Scholar ] [ CrossRef ]

- MX3D Bridge. 2024. Available online: https://mx3d.com/industries/mx3d-bridge/ (accessed on 5 July 2024).

- Connector for Takenaka. Available online: https://mx3d.com/projects/takenaka-connector/ (accessed on 5 July 2024).

- Mechtcherine, V.; Grafe, J.; Nerella, V.N.; Spaniol, E.; Hertel, M.; Füssel, U. 3D-Printed Steel Reinforcement for Digital Concrete Construction—Manufacture, Mechanical Properties and Bond Behaviour. Constr. Build. Mater. 2018 , 179 , 125–137. [ Google Scholar ] [ CrossRef ]

- Müller, J.; Grabowski, M.; Müller, C.; Hensel, J.; Unglaub, J.; Thiele, K.; Kloft, H.; Dilger, K. Design and Parameter Identification of Wire and Arc Additively Manufactured (WAAM) Steel Bars for Use in Construction. Metals 2019 , 9 , 725. [ Google Scholar ] [ CrossRef ]

- Silvestru, V.A.; Ariza, I.; Taras, A. Structural Behaviour of Point-by-Point Wire Arc Additively Manufactured Steel Bars under Compressive Loading. J. Constr. Steel Res. 2023 , 207 , 107982. [ Google Scholar ] [ CrossRef ]

- Silvestru, V.A.; Ariza, I.; Vienne, J.; Michel, L.; Aguilar Sanchez, A.M.; Angst, U.; Rust, R.; Gramazio, F.; Kohler, M.; Taras, A. Performance under Tensile Loading of Point-by-Point Wire and Arc Additively Manufactured Steel Bars for Structural Components. Mater. Des. 2021 , 205 , 109740. [ Google Scholar ] [ CrossRef ]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D Printing of Aluminium Alloys: Additive Manufacturing of Aluminium Alloys Using Selective Laser Melting. Prog. Mater. Sci. 2019 , 106 , 100578. [ Google Scholar ] [ CrossRef ]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N.; Santos, R.; Pedro Mortágua, J. Selective Laser Melting (SLM) and Topology Optimization for Lighter Aerospace Componentes. Procedia Struct. Integr. 2016 , 1 , 289–296. [ Google Scholar ] [ CrossRef ]

- Dimitrov, D.; Uheida, E.; Oosthuizen, G.; Blaine, D.; Laubscher, R.; Sterzing, A.; Blau, P.; Gerber, W.; Damm, O.F.R.A. Manufacturing of High Added Value Titanium Components. A South African Perspective. IOP Conf. Ser. Mater. Sci. Eng. 2018 , 430 , 012009. [ Google Scholar ] [ CrossRef ]

- Saadlaoui, Y.; Milan, J.L.; Rossi, J.M.; Chabrand, P. Topology Optimization and Additive Manufacturing: Comparison of Conception Methods Using Industrial Codes. J. Manuf. Syst. 2017 , 43 , 178–186. [ Google Scholar ] [ CrossRef ]

- Baptista, R.J.S.; Pragana, J.P.M.; Bragança, I.M.F.; Silva, C.M.A.; Alves, L.M.; Martins, P.A.F. Joining Aluminium Profiles to Composite Sheets by Additive Manufacturing and Forming. J. Mater. Process. Technol. 2020 , 279 , 116587. [ Google Scholar ] [ CrossRef ]

- Guo, X.; Kyvelou, P.; Ye, J.; Teh, L.H.; Gardner, L. Experimental Study of DED-Arc Additively Manufactured Steel Double-Lap Shear Bolted Connections. Eng. Struct. 2023 , 281 , 115736. [ Google Scholar ] [ CrossRef ]

- Meng, X.; Zhi, J.; Xu, F.; Gardner, L. Novel Hybrid Sleeve Connections between 3D Printed and Conventional Tubular Steel Elements. Eng. Struct. 2024 , 302 , 117269. [ Google Scholar ] [ CrossRef ]

- Guo, X.; Kyvelou, P.; Ye, J.; Gardner, L. Experimental Investigation of Wire Arc Additively Manufactured Steel T-Stub Connections. J. Constr. Steel Res. 2023 , 211 , 108106. [ Google Scholar ] [ CrossRef ]

- Feucht, T.; Lange, J. 3-D-Printing with Steel: Additive Manufacturing of Connection Elements and Beam Reinforcements. ce/papers 2019 , 3 , 343–348. [ Google Scholar ] [ CrossRef ]

- Lange, J.; Feucht, T.; Erven, M. 3D Printing with Steel: Additive Manufacturing for Connections and Structures. Steel Constr. 2020 , 13 , 144–153. [ Google Scholar ] [ CrossRef ]

- Walton, D.; Moztarzadeh, H. Design and Development of an Additive Manufactured Component by Topology Optimisation. Procedia CIRP 2017 , 60 , 205–210. [ Google Scholar ] [ CrossRef ]

- Hällgren, S.; Pejryd, L.; Ekengren, J. (Re)Design for Additive Manufacturing. Procedia CIRP 2016 , 50 , 246–251. [ Google Scholar ] [ CrossRef ]

- Plocher, J.; Panesar, A. Review on Design and Structural Optimisation in Additive Manufacturing: Towards next-Generation Lightweight Structures. Mater. Des. 2019 , 183 , 108164. [ Google Scholar ] [ CrossRef ]

- Gebisa, A.W.; Lemu, H.G. A Case Study on Topology Optimized Design for Additive Manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2017 , 276 , 012026. [ Google Scholar ] [ CrossRef ]

- Tyflopoulos, E.; Flem, D.T.; Steinert, M.; Olsen, A. State of the Art of Generative Design and Topology Optimization and Potential Research Needs. In Proceedings of the NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [ Google Scholar ]

- Christensen, P.; Klarbring, A. An Introduction to Structural Optimization ; Springer: Dordrecht, The Netherlands, 2008; Volume 153. [ Google Scholar ]

- Rozvany, G.I.N. A Critical Review of Established Methods of Structural Topology Optimization. Struct. Multidiscip. Optim. 2009 , 37 , 217–237. [ Google Scholar ] [ CrossRef ]

- Bendsøe, M.P.; Sigmund, O. Material Interpolation Schemes in Topology Optimization. Arch. Appl. Mech. 1999 , 69 , 635–654. [ Google Scholar ] [ CrossRef ]

- Allaire, G.; Jouve, F.; Toader, A.M. Structural Optimization Using Sensitivity Analysis and a Level-Set Method. J. Comput. Phys. 2004 , 194 , 363–393. [ Google Scholar ] [ CrossRef ]

- Wang, M.Y.; Wang, X.; Guo, D. A Level Set Method for Structural Topology Optimization. Comput. Methods Appl. Mech. Eng. 2003 , 192 , 227–246. [ Google Scholar ] [ CrossRef ]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM Lattice Structures: Properties, Performance, Applications and Challenges. Mater. Des. 2019 , 183 , 108137. [ Google Scholar ] [ CrossRef ]

- Leary, M.; Mazur, M.; Williams, H.; Yang, E.; Alghamdi, A.; Lozanovski, B.; Zhang, X.; Shidid, D.; Farahbod-Sternahl, L.; Witt, G.; et al. Inconel 625 Lattice Structures Manufactured by Selective Laser Melting (SLM): Mechanical Properties, Deformation and Failure Modes. Mater. Des. 2018 , 157 , 179–199. [ Google Scholar ] [ CrossRef ]

- Panesar, A.; Abdi, M.; Hickman, D.; Ashcroft, I. Strategies for Functionally Graded Lattice Structures Derived Using Topology Optimisation for Additive Manufacturing. Addit. Manuf. 2018 , 19 , 81–94. [ Google Scholar ] [ CrossRef ]

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace Applications of Laser Additive Manufacturing. In Laser Additive Manufacturing: Materials, Design, Technologies, and Applications ; Woodhead Publishing: Sawston, UK, 2017; pp. 351–371. ISBN 9780081004333. [ Google Scholar ]

- Gao, J.; Folkes, J.; Yilmaz, O.; Gindy, N. Investigation of a 3D Non-Contact Measurement Based Blade Repair Integration System. Aircr. Eng. Aerosp. Technol. 2005 , 77 , 34–41. [ Google Scholar ] [ CrossRef ]