- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Supply Chain Management Design & Simulation Online

Supply Chain Case Studies

SCM Globe comes with a library of case studies that explore COMMERCIAL , HUMANITARIAN , and MILITARY supply chains. When you purchase an account you have access to all the case studies and their simulations.

The case studies range from relatively simple beginning cases like Cincinnati Seasonings , to quite challenging advanced cases such as Zara Clothing Company , or Nepal Earthquake Disaster Response . Case studies are laboratories where you apply what you learn in lectures and readings to solve supply chain problems in highly realistic simulations. Each case has a " CASE STUDY CONCEPT " showing the supply chain principles and practices highlighted in that case.

SEE WHAT PEOPLE ARE SAYING ABOUT SCM GLOBE

Case studies presently available in the online library are shown below. You are welcome to use any or all of them. You can also create your own case studies, or we can create them for you. Cases are shown in the three categories. As you work with these cases you will gain an intuitive understanding of supply chain dynamics, and develop the analytical skills for designing and managing real supply chains.

People new to SCM Globe should start with the Cincinnati Seasonings case study . Work individually at first, not in groups. Each person needs their own account. Do the three challenges shown in the online introduction to Cincinnati Seasonings. That's how you'll learn to use the software, and how to use simulations to analyze and design supply chains. Then you will be ready to work in groups or work on more advanced cases. Click on the case studies below to see a description and introduction to each case.

Commercial Supply Chain Case Studies

Collaborative Supply Chains

S&J Trading Company – Angola

Java Furniture Company – Indonesia

Cincinnati Seasonings

Supply Chains of the Roman Empire

Ancient Silk Road – First Global Supply Chain

Zara Clothing Company Supply Chain

Fantastic Corporation – Global Supply Chain

Fantastic Corporation – Unexpected Disruptions

Humanitarian supply chain case studies.

Disaster Response Supply Chains: Flooding Scenario

Nepal Earthquake Disaster Response Supply Chain

Humanitarian Supply Chains: Syria Evacuation Scenario (CIV and MIL)

Military supply chain case studies.

Burma Campaign – 1944 Invasion of India

Battle of Smolensk – 1941 Invasion of Russia

Alexander the Great Needed Great Supply Chains

New case studies.

New cases are added based on projects we do with instructors, students, and supply chain professionals. Here are the new supply chain models in the library:

- Local and Sustainable Supply Chains – Blue Ocean Cooperative

- Aerospace Manufacturing Cluster – Rockford IL

- Hyderabadi Biryani – Paramount Restaurant

- Western Desert War – May 1941

- Russian Logistics for the Invasion of Ukraine

Interactive Supply Chain Case Studies

Every case study has a main theme or concept that it illustrates. You will be challenged to use knowledge acquired in lectures and readings as well as your own real-world experience to expand and re-design the supply chains in these case studies.

In the commercial supply chain cases you need to improve and expand the supply chains to support new stores and still keep operating costs and inventory as low as possible. In cases that deal with humanitarian or military missions you need to create supply chains to deliver the right supplies to the right locations when they are needed, and do so at a reasonable cost.

We are glad to provide a free evaluation account to instructors, students and supply chain professionals interested in exploring SCM Globe simulations — click here to request an account — Get Your Free Trial Demo

See SCM Globe pricing for Academic and Business versions of the software.

The best case to start with is Cincinnati Seasonings . After working through the three challenges presented in the online introduction to this case you will be ready to handle further challenges in this case or move on to more advanced cases. Get a quick introduction to working with case studies in “ Working with Case Studies “.

As problems are found in the simulations, you make decisions about how to fix them. Make changes to your supply chain model in the Edit screen. Then go to the Simulate screen and run a simulation to see the results of your changes. Depending on the changes you make, your supply chain simulation runs for additional days and other problems arise. As you address these problems you see about how supply chains work. Apply what you learn in readings and and lectures plus your work experience to solve the problems you encounter.

Keep improving your supply chain model until you get the simulation to run for 30+ days. Then download your simulation results and create a monthly Profit & Loss Report plus KPIs (as shown below). This provides an objective basis for evaluating the merits of different supply chain solutions.

Monthly Profit & Loss Reports identify areas for improvement. They help you improve your supply chain to keep it running for 30 days and also lower operating costs and inventory levels. You can work on lowering the carbon footprint of your supply chain too. These are the challenges you address in SCM Globe, and they are the same challenges people face when managing real supply chains. What works well in the simulations will also work well with actual supply chains. Skills you develop in working with the simulations are directly transferable to the real world.

NOTE: You can run simulations for longer than 30 – 60 days, but there is usually no reason to do so. This is because most companies do not run their supply chains unchanged for longer than 30 days at a time. They use a 30 day S&OP ( sales and operations planning ) cycle and these simulations correspond to that monthly S&OP cycle. These simulations focus on the tactical realities of operating a supply chain from one month to the next, and finding what works best.

Accessing the Online Library of Case Studies

As shown in the screenshots below, logon to your account and access the case study library from your Account Management screen. Click on the “View Library” button (arrow 1) in upper right corner of the Account Management screen. In the Library screen you see a list of available supply chain case studies; click “ Import ” to load a selected case study into your account; give the imported case a Name , and click “ My Account ” to go back to your Account Management screen.

You are welcome to import any or as many of the supply chain models in the library as you wish. Once you have a copy of a supply chain model in your own account you can make any changes you want to it.

In Account Management, you “ Create a New Supply Chain ” or work with an existing supply chain by clicking the “ Edit ” button (arrow 2) next to the existing supply chain you want to work on. You can also upload copies of supply chain models sent to you by other SCM Globe users (arrow 3) , and check your account expiration date (arrow 4) .

Use the Default Values or Enter New Data

When you load any of the case study supply chain models from the SCM Globe library, they come with default numbers already plugged in. You can either accept the defaults or do some research to find more current data. This data (like data and prices everywhere) changes all the time.

Look for data on products, facilities and vehicles that are used in your supply chain and see what their specifications and costs are. Costs can vary widely in different parts of the world. Go to websites of commercial real estate brokers in cities of interest and see what you can find out about rent costs:

- for cities in North America start with www.cityfeet.com

- and for cities in other parts of the world start with www.knightfrank.com

Metric System of Weights and Measures

In the case studies all weights, volumes, distances and speeds are expressed using the metric system. The metric system is used around the world in every country except three: Liberia; Myanmar; and the United States. So it is good for supply chain professionals to feel comfortable with the metric system.

Register on SCM Globe for Access to all Supply Chain Simulations

Click the blue "Register" button on the app login page, and buy an account with a credit card or PayPal (unless you already have one). Then scan the "Getting Started" section, and you are ready to start. Go to the SCM Globe library and click "Import" next to the supply chain models you want.

- BECOME A CONTRIBUTOR

- WHITE PAPERS

- THE SUPPLY CHAIN DICTIONARY

What is Sales & Operations Planning?

The 4 supply chain metrics, static inventory an untapped source of working capital, s&op, a vision for the future. an interview with eric tinker, improving behaviours in support of world class s&op: coach for excellence.

- Planning & Forecasting Articles

How Can Data Improve Supplier Decisions

Information-based negotiations in the digital age, hurt, help or hero how to define and get more out of your most important suppliers, how to spot supplier risk during pickups & deliveries, how to spot supplier risk during on-site evaluations.

- Procurement & Sourcing Articles

The Long Tail of Inventory and Why It’s Important

No more excuses: transformative iot is staring you in the face, predictive analytics let manufacturers see more clearly into their supply chains, rise of the grocers, how 3d printing is set to shake up manufacturing supply chains.

- Manufacturing & Production Articles

6 Tips for Maximizing Efficiency and Productivity of Warehouse Operations

Robot trucks or autonomous vehicles will revolutionize the supply chain, data integration made sexy, how to avoid the most common warehouse safety hazards, out darn spot out, i say.

- Warhouse & Transport Articles

Returns – A Threat to the Bottom Line or an Opportunity to Cut Costs?

Supply chain sustainability takes root, why the 2030 sustainable development goals matter to packaging professionals, to build sustainable products, listen to your customers, getting packaging costs down to size.

- Reverse Logistics Articles

Transform Your Supply Chain For Omnichannel

The impact of maintenance operations on supply chain management, is your supply chain strategy inside-out or outside-in, how industry benchmarks can boost your asset recovery, supply chain visibility: we should be striving for more.

- Supply Chain Management articles

Accelerating the Shift to More Efficient Trucks

Insight – is it ok to lie, supply chain execution software convergence, 3d printing and the supply chains of the future, changing the production performance metric, supply chain management case study: the executive’s guide.

By Supplychainopz

Professionals in supply chain management use various methods to determine how to improve the performance of supply chain operations. Analysis of case study is certainly one of the most popular methods for people from business management background. In order to accelerate the learning, this article has gathered 20+ most sought-after supply chain case studies, analyzed/categorized them by industry and the findings are presented.

Boeing wants to encourage more flight frequency and direct route using a smaller capacity aircraft. Then they decide to outsource many things such as the design, testing and production of key components to key industrial partners and try to reduce number of components that go to assembly. The ultimate goal is to finish the final production process within 3 days. Airbus takes a bit different marketing approach. They want to utilize high capacity airplane to help airlines drive the operating cost down. They decide to selectively outsource the production of parts and keep the design and production of key components in-house.

Supply Chain of fashion industry involves a time based competition. Many customers have the unique product needs but a competition is very fierce because of the low barriers of entry. Many new players try to offer specialized products to customers all the time. This section features the supply chain case studies of H&M, Benetton, Zara and Adidas. – H&M aims to be the price leader in the fashion market.In order to materialize its vision, H&M tries to eliminate the middlemen in various stages of supply chain and consolidate the buying volumes. Product design is also the central part of its strategies. They don’t try to follow the high fashion designs but try to adopt the street trends which are easier to produce. At the end of the day, they can bring products to market within 2-3 weeks. – Benetton , in contrast, chooses to have a full control of its production but allow its licensees to operate the stores so they can focus on production and quality control. The reason is that they would like to create the worldwide brand awareness. For fast moving products, they use the production facilities in Europe. Asian suppliers will perform production for standardized products. – Zara is very famous for its time based strategy. In order to launch a new product within 15 days, Zara uses a small lot production. A new product will be tested in pilot stores. If product sales is good, a larger batch will be ordered. Otherwise, remaining products will be removed from the shelves and sold as mark-down in other stores. This creates the perception among consumers that Zara’s products are unique and you have to take it while stock lasts. Vertical integration contributes to the success of Zara, they own the majority of its production facilities and stores (this is the reason why Quick Response can be effectively implemented). Its automated distribution centers are strategically located between the center of populations so products are delivered to stores quickly. Zara also works with Air France, KLM Cargo and Emirates Air in order that they can coordinate directly with the airlines to make the outbound shipments to its stores and bring back some raw materials and semi-finished materials with return legs. The last supply chain case study in the fashion retailing industry is Adidas . In order to cope with changing customers’ demand, they decide to undertake Mass Customization strategy. The whole idea is to develop, market and deliver the product variety that most customers will find what they want. The first steps towards mass customization is to strategically offer the product choices. Too few variations will disappoint a customer but too many variations will simply postpone a buying decision. After that, Adidas asks the same key suppliers to produce custom components in order to achieve the economy of scale. In order to compensate a long waiting time, Adidas uses air freight or courier service. The reason why they can do this is that customized products are sold directly to customers so they have the higher profit margin to compensate the higher transportation cost. Supply chain strategy of the fashion retailing industry is summarized as below,

FMCG industry is typically the products sold to customers at a low cost and will be completely consumed within 1 year. The nature of this industry is the short product life cycle, low profit margin, high competition and demand fluctuation. This section will present the case studies of P&G, Unilever and Coca-Cola respectively. Forecasting and new product introduction has always been the issues for many FMCG companies, P&G is no exception. To cope with this, P&G conducts a merchandise testing at the pilot stores to determine the customer’s response to new product before the launch. The result is that the forecast accuracy is improved because a demand planner has an additional source data to make a better decision. Moreover, products can be shipped to stores in-time then lost sales is minimal. – Unilever also feels that the competition in FMCG industry has significantly increased. They have to launch the new products on regular basis but the forecasting of new product is difficult. So they create a better classification of new products (base, relaunch, repack, new) using a regression model to identify potential forecast errors for each type of new product. – Coca-Cola doesn’t really have many stock keep units when compared with other companies in the same industry. However, products go to over 2.4 million delivery points through over 430 distribution centers. Managing transportation at this scale is the absolute challenge. In order to streamline the delivery, Coca-Cola implemented a vehicle routing software. The reason is that is the software vendor has a very good relationship with Coca-Cola’s legacy ERP software vendor. Moreover, the vendor has a solid connection with the university who can help to develop the algorithm that fits in with the business’ needs. The result is that transportation planners at each distribution center can use the new tool to reduce travelling time/distance on daily basis.

Lean manufacturing concept has been implemented widely in the automotive industry so the case studies about lean manufacturing is very readily available. Due to the increasing competition in the automobile industry, car manufacturers have to launch a new model to the market more frequently. This section will show you how BMW manages a long term planning, how Ford applies lean concept to the new product development and how Hyundai manages the production planning and control. – BMW uses a 12-year planning horizon and divides it into an annual period. After that, they will make an annual sales forecast for the whole planning horizon. After the demand is obtained, they divide sales into 8 market and then select the appropriate production sites for each market, considering overall capacity constraints and total cost. As you may notice, this kind of a long range planning has to be done strategically. – Ford calls its product development system as “work streams” which include the body development, engine development, prototyping and launch process . The cross-functional team are the experts and their roles are to identify key processes, people, technology necessary for the development of new prototype. Each work stream team is responsible to develop timeline of each process. Detailed plan is usually presented on A3 sized paper. They clearly identifying current issues they are facing with supporting data, drawings and pictures. On weekly basis, they organize a big group meeting of all work stream team to discuss the coordination issues. – Hyundai deploys a centralized planning system covering both production and sales activities across the facilities and functional areas. They develop a 6-month master production plan and a weekly and a daily production schedule for each month in advance. During a short term planning (less than one month), they pay much attention to the coordination between purchasing, production and sales. Providing a long term planning data to its suppliers help to stabilize production of its part makers a lot.

Life cycle of technology products is getting shorter and shorter every day. Unlike FMCG, the launch of a new product in the hi-tech industry requires the investment in research and development quite extensively. Then, a poor planning will result in a massive loss. This section will cover JIT and outsourcing by Apple Inc, Supply Chain Risk Management by Cisco System, Technology Roadmap by Intel, Supply Chain Network Model by HP, Mass Customization by Dell and Quality Management by Sam Sung. Steve Jobs invited the Tim Cook to help to improve Apple’s Supply Chain in 1998. Jobs told Cook that he visited many manufacturing companies in Japan and he would like Cook to implement the JIT system for Apple. Jobs believed that Apple’ supply chain was too complex then both of them reduced the number of product availability and created 4 products segment, reduced on hand inventory and moved the assembling activities to Asia so they could focus on developing the breathtaking products that people wanted to buy. – Cisco Systems would like to be the brand of customer choice so they implement a very comprehensive supply chain risk management program by applying basic risk mitigation strategies, establishing appropriate metrics, monitoring potential supply chain disruptions on 24/7 basis and activate an incident management team when the level of disruption is significant. – Intel ‘s new product development is done by the process called Technology Roadmap. Basically, it’s the shared expectations among Intel, its customers and suppliers for the future product lineup. The first step to prepare the roadmap is to identify the expectations among semiconductor companies and suppliers. Then they identify key technological requirements needed to fulfill the expectations. The final step is to propose the plan to a final meeting to discuss about the feasibility of project. Some concerning parties such as downstream firms may try to alter some aspects of the roadmap. Technology Roadmap allows Intel to share its vision to its ecosystem and to utilize new technology from its suppliers. – HP ‘s case study is pretty unique. They face with a basic question, where to produce, localize and distribute products. Its simple supply chain network model is presented below,

From this example, only 3 possible locations result in 5 different way to design the supply chain. In reality, HP has more production facilities than the example above so there are so many scenarios to work with. How should HP decide which kind of a supply chain network configuration they should take to reduce cost and increase service to customer? The answer is that they use the multi-echelon inventory model to solve the problem. – Dell is one of the classic supply chain case studies of all time. Many industries try to imitate Dell’s success. The key ingredients of Dell’s supply chain are the partnership with suppliers, part modularity, vendor managed inventory program, demand management and mass customization. Also, you can find the simplified process map of Dell’s order-to-cash process as below,

– Sam Sung has proven to be the force to be reckoned with in the hi-tech industry. The secret behind its supply chain success is the use of Six Sigma approach. They studied how General Electric (GE), DuPont and Honeywell implemented six sigma. After that, they have created their own implementation methodology called DMAEV (define, measure, analyze, enable, verify). They use the global level KPI to ensure that each player in the same supply chain is measured the same way. Also, they utilize SCOR Model as the standard process. Any process changes will be reflected through an advance planning system (APS).

The last industry covered here is the general merchandise retailing industry. The critical success factor of this industry is to understand the drivers of consumer demand. Four case studies will be presented, namely, 7-11, Tesco, Walmart, Amazon and Zappos. – 7/11 is another popular case study in supply chain management. The integration of information technology between stores and its distribution centers play the important role. Since the size of 7/11 store is pretty small, it’s crucial that a store manager knows what kind of products should be displayed on shelves to maximize the revenue. This is achieved through the monitoring of sales data every morning. Sales data enables the company to create the right product mix and the new products on regular basis. 7/11 also uses something called combined delivery system aka cross docking. The products are categorized by the temperature (frozen, chilled, room temperature and warm foods). Each truck routes to multiple stores during off-peak time to avoid the traffic congestion and reduce the problems with loading/unloading at stores. – Tesco is one of the prominent retail stores in Europe. Since UK is relatively small when compared with the United States, centralized control of distribution operations and warehouse makes it easier to manage. They use the bigger trucks (with special compartments for multi-temperature products) and make a less frequent delivery to reduce transportation cost. Definitely, they use a computerized systems and electronic data interchange to connect the stores and the central processing system. – Wal-Mart ‘s “Every Day Low Prices” is the strategy mentioned in many textbooks. The idea is to try not to make the promotions that make the demand plunges and surges aka bullwhip effect. Wal-Mart has less than 100 distribution centers in total and each one serves a particular market. To make a decision about new DC location, Walmart uses 2 main factors, namely, the demand in the proposed DC area and the outbound logistics cost from DC to stores. Cost of inbound logistics is not taken into account. There are 3 types of the replenishment process in Wal-Mart supply chain network as below,

In contrary to general belief, Wal-mart doesn’t use cross-docking that often. About 20% of orders are direct-to-store (for example, dog food products). Another 80% of orders are handled by both warehouse and cross dock system. Wal-Mart has one of the largest private fleet in the United States. The delivery is made 50% by common carriers and 50% by private fleet. Private fleet is used to perform the backhauls (picks up cargoes from vendors to replenish DCs + sends returned products to vendors). Short-hauls (less than one working day drive) is also done by the a private fleet. For long-hauls, the common carriers will be used. There are 2 main information system deployed by Wal-Mart. “Retail Link” is the communication system developed in-house to store data, share data and help with the shipment routing assignments. Another system is called “Inforem” for the automation of a replenishment process. Inforem was originally developed by IBM and has been modified extensively by Wal-Mart. Inforem uses various factors such as POS data, current stock level and so on to suggest the order quantity many times a week. Level of collaboration between Wal-Mart and vendors is different from one vendor to the other. Some vendors can participate in VMI program but the level of information sharing is also different. VMI program at Wal-Mart is not 100% on consignment basis. – Amazon has a very grand business strategy to “ offer customers low prices, convenience, and a wide selection of merchandise “. Due to the lack of actual store front, the locations of warehouse facilities are strategically important to the company. Amazon makes a facility locations decision based on the distance to demand areas and tax implications. With 170 million items of physical products in the virtual stores, the back end of order processing and fulfillment is a bit complicated. Anyway, a simplified version of the order-to-cash process are illustrated as below,

Upon receipt of the orders, Amazon assign the orders to an appropriate DC with the lowest outbound logistics cost. In Amazon’s warehouse, there are 5 types of storage areas. Library Prime Storage is the area dedicated for book/magazine. Case Flow Prime Storage is for the products with a broken case and high demand. Pallet Prime Storage is for the products with a full case and high demand. Random Storage is for the smaller items with a moderate demand and Reserve Storage will be used for the low demand/irregular shaped products. Amazon uses an propitiatory warehouse management system to make the putaway decision and order picking decision. After the orders are picked and packed, Amazon ships the orders using common carriers so they can obtain the economy of scale. Orders will arrive at UPS facility near a delivery point and UPS will perform the last mile delivery to customers. Amazon is known to use Sales and Operations Planning (S&OP) to handle the sales forecast. Anyway, this must be S&OP process at product family/category level. To compete with other online retailers, Zappos pays much attention to the way they provide the services to customers. In stead of focusing on the call center productivity, Zappos encourages its staff to spend times over the phone with customers as long as they can so they can fully understand the customer’s requirements. They also upgrade the delivery from 3 days to 1 day delivery in order to exceed customer expectation.

All case study demonstrates that supply chain management is truly the strategic initiatives, not merely a cost cutting technique. Leading companies have a very strong customer focus because almost all of initiatives are something to fill the needs of customers. Relationship management is the unsung hero in supply chain management. It’s the prerequisite to the success of every supply chain. And at the end of the day, it comes down to the quality of supply chain people who analyze, improve and control supply chain operations. – See more at: http://www.supplychainopz.com/2014/04/supply-chain-management-case-study.html#sthash.MrnrGsyY.dpuf

Supply Chain Minded is a very active and fast growing online community in Supply Chain for Planning, Sourcing, Manufacturing, Delivery and Reverse Logistics professionals. The Supply Chain Minded community aims to inform and connect professionals active in Supply Chain, Purchasing, Manufacturing, Warehousing, Transport, Distribution; Reverse Logistics, Service Logistics, Lean & Six Sigma, 3PL.

© Copyright - Supply Chain Minded 2023

- SUGGESTED TOPICS

- The Magazine

- Newsletters

- Managing Yourself

- Managing Teams

- Work-life Balance

- The Big Idea

- Data & Visuals

- Reading Lists

- Case Selections

- HBR Learning

- Topic Feeds

- Account Settings

- Email Preferences

Case Study: How Should We Diversify Our Supply Chain?

- Krishna G. Palepu

A Chinese appliance maker considers expanding production to Mexico.

In the wake of Covid-19’s disruptions, Kshore, a Chinese appliance maker, is thinking of realigning its supply chain. Like many other global manufacturers, it’s being pressured by its customers, which include Walmart and other large retailers, to reduce the time, expense, and environmental impact of shipping goods between countries.

On a trip to Monterrey, Mexico, Kshore’s CEO and COO tour factories that are closer to North American markets—and are impressed by their professionalism. But questions about transportation and staffing give the executives pause. Should Kshore start production in Mexico or consider other countries? Two experts weigh in.

On the sidewalk outside the airport in Mexico City, Yun Liu and Keith Smith, the CEO and COO of Kshore, a Chinese appliance maker with $150 million in annual revenues, waited for their town car. Their journey from Guangzhou, China, had been a long one.

- Krishna G. Palepu is the Ross Graham Walker Professor of Business Administration at Harvard Business School. His research focuses on globalization, emerging markets, and strategies for multinational and local companies in those markets. He cochairs the HBS executive program Leading Global Businesses.

Partner Center

Brought to you by:

Walmart: Supply Chain Management

By: P. Fraser Johnson, Ken Mark

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to…

- Length: 16 page(s)

- Publication Date: Jul 8, 2019

- Discipline: Operations Management

- Product #: W19317-PDF-ENG

What's included:

- Teaching Note

- Educator Copy

$4.95 per student

degree granting course

$8.95 per student

non-degree granting course

Get access to this material, plus much more with a free Educator Account:

- Access to world-famous HBS cases

- Up to 60% off materials for your students

- Resources for teaching online

- Tips and reviews from other Educators

Already registered? Sign in

- Student Registration

- Non-Academic Registration

- Included Materials

This case focuses on the supply chain strategy of Walmart. Set in 2019, it provides a detailed description of the company's supply chain network and capabilities. Data in the case allows students to compare Walmart's source of competitiveness with those of other retailers-both online including Amazon.com and traditional brick-and-mortar retailers, such as Target-to develop insights into the management of a large, complex, global supply chain network. As competition between Walmart and its online and offline competitors heated up, a key challenge for the company's president and chief executive officer was deciding what changes made to Walmart's expanding supply chain would best support its strategic objectives. What supply chain capabilities would Walmart need as its business model continued to evolve?

Learning Objectives

This case can be used in an undergraduate or MBA course in supply chain management, operations management, business strategy, international business, logistics, purchasing, or marketing. It can provide an introduction to supply chain management using a company with which most students are familiar. In doing so, it allows students to learn how Walmart has built up its supply chain capabilities over the past five decades, and how the company leveraged these capabilities to become the world's largest retailer. Combining the Walmart case with the "Amazon.com: Supply Chain Management" case (W18451) in back-to-back classes provides a powerful illustration of the differences between two leading companies and demonstrates the importance of alignment of supply chain competencies with organizational strategy. After completion of this case, students will be able to: Assess Walmart's supply chain and identify its key competitive advantages. Quantify Walmart's ability to generate value from its supply chain. Identify potential opportunities and challenges for Walmart to improve its supply chain. Analyze the effects of the opportunities and challenges facing Walmart on its growth and evolution.

Jul 8, 2019 (Revised: Sep 9, 2019)

Discipline:

Operations Management

Geographies:

United States

Industries:

Retail trade

Ivey Publishing

W19317-PDF-ENG

We use cookies to understand how you use our site and to improve your experience, including personalizing content. Learn More . By continuing to use our site, you accept our use of cookies and revised Privacy Policy .

SCM Case Studies With Examples

What is an scm case study.

- Procurement

- Product lifecycle management (PLM)

- Inventory management

- Demand planning

- Order management

- Warehousing

- Transportation

- Customer service

What’s Included in SCM Case Studies?

- Client profile —company type, industry, and a brief history and description of the company

- The situation —the circumstances that initially caused the company to become interested in a new SCM solution

- The challenges —the problems and issues the company was facing that an SCM solution could solve

- The process —the heart of the case study, as it shows how the SCM vendor, reseller, or service provider—or TEC—performed its services in a way that met or exceeded the client’s goals and expectations

- The results —the benefits to the client at the end of the day

- Vendor/service provider profile —brief description of the vendor, reseller, or service provider—or TEC—including contact information

The Benefits of an SCM Case Study in the Selection Process

Because modern SCM software is generally quite complex, it can be difficult for companies to determine which SCM solution is the right one for their needs. Fortunately, there is a lot of documentation and research that companies can reference to assist them. As a category, SCM case studies can be of particular value because they describe how other companies overcame challenges inherent in the SCM software selection process. In the best case, organizations, such as manufacturing and distribution companies, can find SCM case studies that feature companies like theirs with similar needs and circumstances.

How TEC's SCM Case Studies Can Help You Find the Best-Fit SCM Software

TEC is a software service provider; we are not a vendor or reseller. As an industry-leading software advisory firm, we focus on three areas that are of critical importance to our clients:

- evaluation and selection

- implementation oversight

- vendor/reseller contract negotiations

TEC case studies show how our advisory services helped companies of varying types, sizes, and industries succeed in all three areas.

TEC’s SCM Software Selection Process

Selecting enterprise software presents some significant issues. The complexity of today’s enterprise software can be a challenge for companies that lack the appropriate in-house expertise. Most companies are unused to cataloging their processes and goals and then matching them to software features and functions. And while vendors sell software every day, companies seldom make a software purchase, giving vendors a built-in advantage when it comes to contract negotiations. Finally, software implementation is a specialty of its own, requiring specific expertise and oversight in this process. As you can see right below, TEC’s software selection process provides assistance in all these areas with a proven methodology developed over hundreds of successful selection projects and implementations.

- Assess : Assess the client’s business processes and goals, gaps in key processes, and discover their functional requirements

- Review : Review SCM solutions and vendor capabilities to meet the client’s business needs

- Identify : Identify the shortlist of SCM vendors and their partner(s)

- Demonstration : Assess SCM solution demonstrations scripted to the client’s business processes

- Proposal : Create and distribute SCM request for proposal (RFP) to vendors to clarify deliverables and project total cost of ownership (TCO)

- Reference : Evaluate SCM vendor and their partner(s) through reference checks from real-world clients on previous projects

- Contract : Perform contract review and price negotiations on behalf of the client for cost savings

- Implementation : Perform oversight and monitor the implementation of the SCM application(s) to enable successful transformation and business growth

TEC’s proven methodology is backed by our decision support software TECAdvisor , ensuring that every software selection decision is driven by data and is an impartial evaluation of the current enterprise software market.

Learn More with Our Free Library of SCM Case Studies

Refine results.

- Enterprise Resource Planning (ERP) 536

- Discrete Manufacturing ERP 127

- Process Manufacturing ERP 122

- Mixed-Mode ERP 112

- ERP for Small Manufacturing Business 100

- Distribution ERP 83

- ERP for Service Industry 35

- ERP for Small Business 33

- Engineer-to-Order (ETO) 121

- Supply Chain & Logistics 299

- Supply Chain Management (SCM) 158

- Inventory Management 87

- Manufacturing Execution Systems (MES) 57

- Merchandising Software 18

- Supply Relationship Management (SRM) 29

- Transportation Management Systems (TMS) 25

- Demand Management Software 27

- RFID Software 5

- Warehouse Management Systems (WMS) 97

- Business Intelligence & Data Analytics 247

- Spreadsheet 1

- Business Process Management (BPM) 100

- Enterprise Performance Management 60

- Business Intelligence (BI) and Data Management 181

- Customer Relationship Management & Support 219

- Call Center 6

- Event Management 1

- Proposal Management 10

- Contract Management 2

- Sales Force Automation Software 21

- Customer Relationship Management (CRM) 185

- Field Service Management (FSM) 80

- Configure Price Quote (CPQ) 33

- Benefits Administration 12

- Compensation Management 6

- Human Resources 24

- Performance Management 14

- Time & Attendance 11

- Workforce Management 15

- Learning Management Systems (LMS) 75

- Talent Acquisition Software 14

- Talent Management Systems 43

- Human Capital Management (HCM) 83

- Financial 130

- Billing & Invoicing 17

- Point of Sale (POS) 2

- Accounting and Financial Software 85

- Asset Management 122

- Facility Management 6

- Computerized Maintenance Management System 109

- Asset Management (EAM) 97

- Product Lifecycle Management (PLM) 115

- Process PLM 15

- Discrete PLM 16

- Regulatory and Compliance PLM 26

- Fashion PLM 22

- Retail PLM 48

- Information & Document Management 69

- Document Management Systems (DMS) 58

- Enterprise Content Management (ECM) 52

- Content Management System (CMS) 17

- IT & IT Security 57

- Help Desk 6

- Virtual Private Network (VPN) 1

- Remote Access 3

- Network Security 16

- E-commerce 31

- Web Content Management (WCM) 6

- Communication & Collaboration 31

- Collaboration 2

- Project Management 8

- Project and Process Management (PPM) 23

- Marketing 23

- Marketing Automation 23

- Design/Creative 9

- Computer-Aided Design (CAD) 9

- Industry-Specific 3

- Property Management 3

- Manufacturing 41

- Wholesale and Retail Trade 21

- Food and Beverage Products 8

- Chemical Products 5

- Pharmaceutical and Botanical Products 4

- Transportation 4

- Construction 3

- Motor Vehicles and Other Transport Equipment 3

- Agriculture and Forestry 2

- Health Care and Social Work 2

- Hotels and Restaurants 2

- Life and Natural Sciences 2

- Mining & Quarrying 2

- Public Administration and Defense 2

- Publishing and Media 2

- Telecommunications 2

- Warehousing 2

- Electronics and High-tech Components 1

- Industry Independent 1

- Insurance 1

- Recreational, Cultural, and Sporting Activities 1

Publication Types

- Blog Posts 1,216

- White Papers 772

- Case Studies 158

- Industry Reports 65

- Brochures 41

- Software Reviews 40

- Buyer's Guides 14

- Datasheets 14

- Accreditation Reports 6

- Plex Systems 9

- Pronto Software 7

- Synergy Resources 6

- Technology Evaluation Centers 6

- Demand Management Inc. 5

- Microsoft 5

- Blue Yonder 4

- AFS Technologies, Inc. 3

- Bamboo Rose 3

- MSM Solutions 3

- AppFinity Software Corp. 2

- Cadre Technologies, Inc 2

- Cameleon Software 2

- Chiron Technologies, Inc. 2

- Dassault Systèmes 2

- Habanero Consulting Group 2

- LOGO Business Solutions 2

- NGC (New Generation Computing) 2

- Nucleus Research 2

- Waer Systems Limited 2

- Arena Solutions (a PTC Business) 1

- Know the option you’re looking for? Type in the search field.

Top Publications

Big data and the supply chain: The big-supply-chain analytics landscape (Part 1)

Big data and the era of digital means a big analytics landscape for supply chain to work with.

Your supply chains generate big data. Big supply-chain analytics turn that data into real insights.

The explosive impact of e-commerce on traditional brick and mortar retailers is just one notable example of the data-driven revolution that is sweeping many industries and business functions today. Few companies, however, have been able to apply to the same degree the "big analytics" techniques that could transform the way they define and manage their supply chains.

In our view, the full impact of big data in the supply chain is restrained by two major challenges. First, there is a lack of capabilities. Supply chain managers—even those with a high degree of technical skill—have little or no experience with the data analysis techniques used by data scientists. As a result, they often lack the vision to see what might be possible with big data analytics. Second (and perhaps more significantly), most companies lack a structured process to explore, evaluate and capture big data opportunities in their supply chains.

In the second part of this article series, we will show how companies can take control of the big data opportunity with a systematic approach. Here, we will look at the nature of that opportunity and at how some companies have managed to embed data driven methodologies into their DNA. Exhibit 1 provides an overview of the landscape of supply chain analytics opportunities.

What is big supply-chain analytics?

Big supply chain analytics uses data and quantitative methods to improve decision making for all activities across the supply chain. In particular, it does two new things. First, it expands the dataset for analysis beyond the traditional internal data held on Enterprise Resource Planning (ERP) and supply chain management (SCM) systems. Second, it applies powerful statistical methods to both new and existing data sources. This creates new insights that help improve supply chain decision-making, all the way from the improvement of front-line operations, to strategic choices, such as the selection of the right supply chain operating models.

Let's look at each main area in turn.

A. Sales, Inventory and Operations Planning

Typically, planning is already the most data-driven process in the supply chain, using a wide range of inputs from Enterprise Resource Planning (ERP) and SCM planning tools. There is now significant potential to truly redefine the planning process, however, using new internal and external data sources to make real-time demand and supply shaping a reality.

We can think about managing inventory in a supply chain similar to the way electricity is managed: Storing electricity is expensive and difficult; power companies bring in additional consumers or start and stop plants to ensure a balanced power grid. Retailers now have the opportunity to use a similar approach. Visibility of point of sale (POS) data, inventory data, and production volumes can be analyzed in real time to identify mismatches between supply and demand. These can then drive actions, like price changes, the timing of promotions or the addition of new lines, to realign things.

Retailers can also use new data sources to improve planning processes and their demand-sensing capabilities. For example, Blue Yonder has developed data intensive forecasting methods now deployed into retailing where 130,000 SKUs and 200 influencing variables generate 150,000,000 probability distributions every day. This has dramatically increased forecast accuracy; enabled a better view of the company's logistics capacity needs; and reduced obsolescence, inventory levels, and stockouts. The recent growth of third party cloud-based services like Blue Yonder is making such activities more accessible for other retailers, too.

Similarly, IBM has helped develop links between production planning and weather forecasts for bakeries. By incorporating temperature and sunshine data, baking companies are able to more accurately predict demand for different product categories based on factors that influence consumer preferences. Amazon, meanwhile, has patented an "anticipatory shipping" approach, in which orders are packaged and pushed into the delivery network before customers have actually ordered them.

Having truly mastered big-data forecasting, the next level of sophistication is to start actively shaping demand. Leading online retailers, for example, use big data analytics, inventory data, and forecasting to change the products recommended to customers. This effectively steers demand towards items that are available in stock.

B. Sourcing

In many companies, data on procurement volumes and suppliers are only gathered for few activities in the sourcing process. However, supply data goes beyond the classic spend analysis and annual supplier performance review. On a transactional basis, supply processes can be sensed in real time to identify deviations from normal delivery patterns. Firms are also finding opportunities for predictive risk management. By mapping its supply chains and using "Google trend"-style information and social data about strikes, fires, or bankruptcies, a firm can monitor supply disruptions in transportation, or at 2nd or 3rd tier suppliers, and take decisive actions before its competitors.

Data analysis can also drive strategic decisions. In recent years, one pharmaceutical company has created a database with all bids submitted for packaging. The data has been evaluated to fully understand the cost structure of those suppliers and to create detailed cost models for different types of packaging. Using updated information on commodity prices, factor costs, and plant utilization, these models can be used to aid the selection of the most appropriate suppliers for new packaging projects. Similarly, Caterpillar has initiated a contest on the crowd-data science website Kaggle to model quoted prices for industrial tube assemblies.

These "clean sheet costing" bottom-up calculations can also be applied in the purchase of transportation and warehousing. By exploiting data on the cost breakdown of operations of trucks and warehouses across the globe, companies do create a powerful fact base to challenge carriers and Logistics Solution Providers (LSPs), and provide real insight into "should cost" during negotiations.

C. Manufacturing

Big data and analytics can already help improve manufacturing. For example, energy-intensive production runs can be scheduled to take advantage of fluctuating electricity prices. Data on manufacturing parameters, like the forces used in assembly operations or dimensional differences between parts, can be archived and analyzed to support the root-cause analysis of defects, even if they occur years later. Agricultural seed processors and manufacturers analyze the quality of their products with different types of cameras in real-time to get the quality assessments for each individual seed.

The Internet of Things, with its networks of cameras and sensors on millions of devices, may enable other manufacturing opportunities in the future. Ultimately, live information on a machine's condition could trigger production of a 3D-printed spare part that is then shipped by a drone to the plant to meet an engineer, who may use augmented reality glasses for guidance while replacing the part.

D. Warehousing

Logistics has traditionally been very cost-focused, and companies have happily invested in technologies that provide competitive advantage. Warehousing in particular has seen many advances using available ERP data. One example are "chaotic" storage approaches that enable the efficient use of warehouse space and minimize travel distances for personnel. Another are high-rack bay warehouses that can automatically reshuffle pallets at night to optimize schedules for the next day. Companies can track the performance of pickers in different picking areas to optimize future staff allocation.

New technologies, data sources and analytical techniques are also creating new opportunities in warehousing. A leading forklift provider is looking into how the forklift truck can act as a big data hub that collects all sorts of data in real time, which can then be blended with ERP and Warehouse Management System (WMS) data to identify additional waste in the warehouse process. For example, the analysis of video images collected by automated guided vehicles, along with sensor inputs including temperature, shelf weight, and the weight on the forklift, can be used to monitor picking accuracy, warehouse productivity and inventory accuracy in real time. Similarly forklift driving behavior and route choices can be assessed and dynamically optimized to drive picking productivity. The data can also be used to conduct root-cause analysis of picking errors by shape, color, or weight, to help to make processes more robust.

New 3D modelling technologies can also help to optimize warehouse design and simulate new configurations of existing warehouse space to further improve storage efficiency and picking productivity. German company Logivations, for example, offers a cloud-based 3D warehouse layout planning and optimization tool.

E. Transportation

Truck companies already make use of analytics to improve their operations. For example, they use fuel consumption analytics to improve driving efficiency; and they use GPS technologies to reduce waiting times by allocating warehouse bays in real time.

Courier companies have started real-time routing of deliveries to customers based on their truck's geo-location and traffic data. UPS, for example has spent ten years developing its On-Road Integrated Optimization and Navigation system (Orion) to optimize the 55,000 routes in the network. The company's CEO David Abney says the new system will save the company $300 million to $400 million a year.

Big analytics will also enable logistics providers to deliver parcels with fewer delivery attempts, by allowing them to mine their data to predict when a particular customer is more likely to be at home. On a more strategic basis, companies can cut costs and carbon emissions by selecting the right transport modes. A major CPG player is investing in analytics that will help it to understand when goods need be shipped rapidly by truck or when there is time for slower barge or train delivery.

F. Point of Sale

Brick and mortar retailers—often under heavy pressure from online competitors that have mastered analytics—have understood how datadriven optimization can provide them with competitive advantages. These techniques are being used today for activities like shelf-space optimization and mark-down pricing. Advanced analytics can also help retailers decide which products to put in high value locations, like aisle ends, and how long to keep them there. It can also enable them to explore the sales benefits achieved by clustering related products together.

Search engine giant Google has acquired Skybox, a provider of highresolution satellite imagery, that can be used to track cars in the car park in order to anticipate in-store demand. Others have explored the use of drones equipped with cameras to monitor on-shelf inventory levels.

A topic that is still a challenge for many retailers is out-of-stock detection and prevention. In developed markets, manual inspections are expensive, while RFID tags still cost too much to be applied to individual grocery items. Instead, retailers are now monitoring sales activity for out of stock indicators. If an item that usually sold every few minutes does not appear at the tills, an alert is triggered to have person check if the item is out of stock at the shelf. Other innovative technologies are also being tested, including the installation of light or weight sensors on shelves as well as the use of in-store cameras to monitor on-shelf stock levels.

Similar technologies can be applied directly at the point of use. Amazon's Dash service, for example provides consumers with wireless buttons that can be used to reorder domestic products with a single push, like washing powder or razor blades. Ultimately, stores may be able to link to data gathered from consumer's Internet-connected refrigerators to forecast demand in real time.

As the examples in this article show, big data is already helping leading organizations transform the performance of their supply chains. Today, such approaches are the exception rather than the norm, however. Lack of capabilities and the lack of a structured approach to supply chain big data is holding many companies back. For big data and advanced analytical tools to deliver greater benefits for more companies, those organizations need a more systematic approach to their adoption. Part 2 of this series will address that topic in detail.

About the authors: Knut Alicke is a master expert in the Stuttgart office, Christoph Glatzel is a director in the Cologne office, and Per-Magnus Karlsson is a consultant in the Stockholm office. Kai Hoberg is an associate professor of supply chain and operations strategy at Kühne Logistics University, Germany.

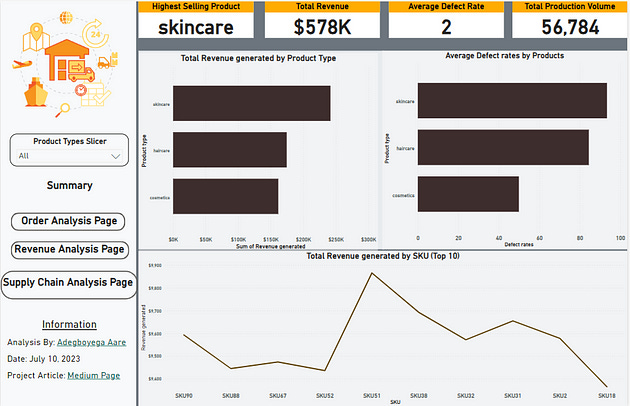

Supply Chain Analysis: Data Analysis Case Study Using Excel

A supply chain analysis project using microsoft excel and microsoft power bi..

Supply chain analytics plays a crucial role in driving data-driven decision-making across industries, including manufacturing, retail, healthcare, and logistics. In this report, I presented an analysis of a Fashion and Beauty startup’s supply chain data, specifically focused on the movement of makeup products. By collecting, analyzing, and interpreting this dataset, I aim to gain insights that can inform strategic decisions and optimize supply chain operations.

Dataset Overview

The dataset comprises various features related to the fashion and makeup product supply chain. These features provide valuable information for understanding the flow of products from suppliers to customers. The following features include:

Product Type

Availability

Number of products sold

Revenue generated

Customer demographics

Stock levels

Order quantities

Shipping times

Shipping carriers

Shipping costs

Supplier name

Production volumes

Manufacturing lead time

Manufacturing costs

Inspection results

Defect rates

Transportation modes

Supply Chain Analysis using Excel

The supply chain represents a network of interconnected processes involved in the production and delivery of goods to customers. Analyzing the various components of a supply chain is crucial for identifying opportunities to enhance its effectiveness and generate greater value for customers. In this report, I conducted a supply chain analysis using Excel and gave valuable insights into optimizing supply chain operations.

Dataset Source

To perform a supply chain analysis on this company, it is crucial to gather data related to various stages of the supply chain. This includes information on sourcing, manufacturing, transportation, inventory management, sales, and customer demographics.

Fortunately, I have come across this excellent dataset that provides comprehensive data about the supply chain of a Fashion and Beauty startup.

In the following section, I will guide you through the process I use to conduct a supply chain analysis using Excel.

Dataset from Github

Dataset Analysis using Excel

The first step is to import the file into Excel.

After importing the file, the next task is to remove any duplicate entries. To do this, I selected all the data by clicking on cell A1 and then pressed Ctrl+A. Then click on the “Data” tab and choose “Remove Duplicates” under the “Data Tools” section. Once duplicates are removed, the next step is to filter the data to identify any spelling errors or unwanted names. To do this, I can click on the “Filter” tool under the “Sort & Filter” section. While filtering, I noticed that some entries under the “Customer Demographics” category are labelled as “Unknown” instead of specific demographics like Male, Female or Non-Binary. Since I won’t be using this data, I proceeded with the existing information. At this stage, the data cleaning process is considered complete, and I have moved on to the next steps.

To facilitate further analysis, I converted the data into a table. I achieved this by selecting the entire data range (Ctrl+A) and then pressing Ctrl+T to convert it into a table. The next step is to create a pivot table. Navigated to the “Insert” tab and select the “PivotTable” tool. Choose the location for the pivot table (such as a new worksheet) and specify the data range (Table 1 or the relevant table name). Once the pivot table was created, I formatted the numbers to display as whole numbers and removed any decimal places for better readability.

A. Now, I’m ready to analyze the data and provide insights based on the following requirements or objectives.

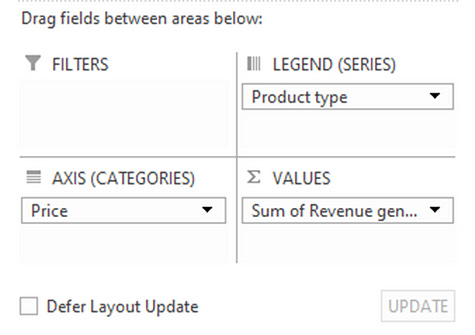

I begin the analysis of the Supply Chain by examining the correlation between product prices and the corresponding revenue they generate.

Therefore, the company generates a higher revenue from skincare products, and there is a positive relationship between the price of skincare products and the revenue they generate.

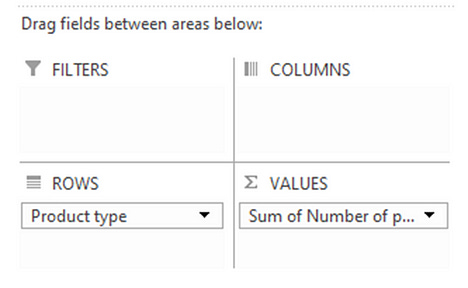

B. Now, I examined the sales based on different product types.

Skincare products account for 45% of the company’s business, while haircare products contribute to 29.5% of the revenue, and cosmetics make up 25.5% of the total sales.

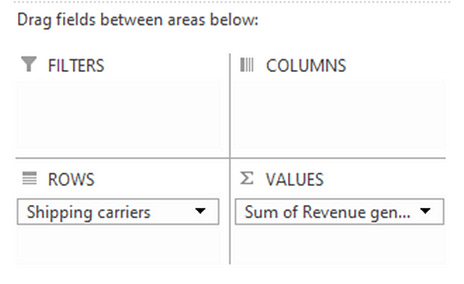

C. Now, I analyzed the total revenue generated from shipping carriers.

The company utilizes three shipping carriers for transportation, and among them, Carrier B contributes significantly to the company’s revenue generation.

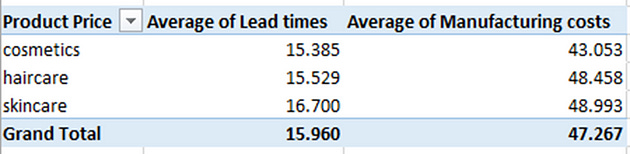

D. Now, I examined the average lead time and average manufacturing costs for all products of the company.

Analyzing SKUs

In the dataset, there is a column labelled SKUs, which stands for Stock Keeping Units. SKUs are unique codes assigned to products to facilitate inventory management and tracking. They serve as a means to identify and differentiate individual items, ensuring accurate monitoring of stock levels. For instance, in a toy store with a diverse range of toys, each toy would be assigned a unique SKU as a secret number known only to the store, enabling efficient inventory control.

A. Now, I analyzed the revenue generated by each SKU.

Another column in the dataset is labelled Stock levels. Stock levels indicate the quantity of products available in a store or business’s inventory at a given time

B. Now, I examined the stock levels of each SKU.

C. Now, I analyzed the order quantity of each SKU.

Cost Analysis

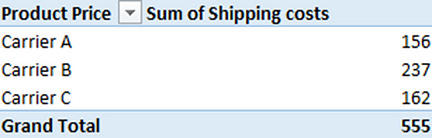

A. Now, I analyzed the shipping costs associated with different carriers.

The above visualizations revealed that Carrier B contributes significantly to the company’s revenue. However, it is also the most expensive carrier among the three options.

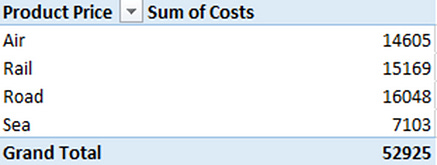

B. Now, I examined the distribution of costs by transportation mode.

The company allocates a larger portion of its transportation expenses to the Road and Rail modes for the transportation of goods.

Analyzing Defect Rate

The defect rate in the supply chain refers to the percentage of products that are found to have issues or are damaged after being shipped.

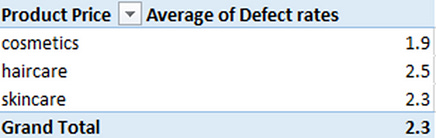

A. Now, I analyzed the average defect rate across all product types.

Haircare products have a higher defect rate compared to other product types.

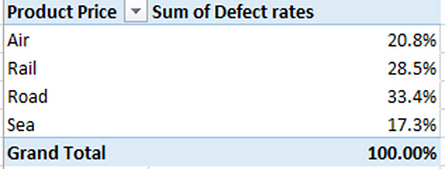

B. Now, I examined the defect rates based on the mode of transportation.

Road transportation exhibits a higher defect rate, while Air transportation demonstrates the lowest defect rate. This showcases how Excel programming language can be utilized to analyze a company’s supply chain.

I successfully created a dashboard using Power BI that presents the insights mentioned earlier. The dashboard effectively highlights essential revenue-related information, including:

1. Revenue generated from each supplier. 2. Revenue generated from each location. 3. Revenue generated from each company product. 4. Total products delivered by each carrier.

These insightful visualizations offer valuable data-driven perspectives, enabling informed decision-making and strategic planning.

Supply Chain Analysis involves examining different aspects of a supply chain to identify areas for improvement and enhance the overall efficiency of the supply chain, ultimately delivering greater value to customers. This report provided an overview of conducting a supply chain analysis using Excel, highlighting key steps and techniques and revenue generated.

Thank you for reading, for more guides like this follow me on;

Twitter || LinkedIn

Buy Me a Coffee

If you find this article insightful you can support me by buying me a coffee (Click HERE ).

Remember to like, share, comment and subscribe.

Ready for more?

- Software Categories

Get results fast. Talk to an expert now.

855-718-1369

Creating an omnichannel supply chain: a macy’s case study.

In February 2020, Macy’s announced their Polaris plan , a three-year strategy created to stabilize profits and create growth. This plan included closing 125 underperforming stores and consolidating offices. It also included a major overhaul of their supply chain model.

But, of course, Macy’s had to close their doors less than 6 weeks later due to COVID-19. As their online presence was the only presence available, their longstanding supply chain strategy, which was already starting to cause major issues within the company, needed immediate attention.

Macy’s CEO Jeff Gennette stated in September 2020, “Everything on the digital agenda has been accelerated. We’re optimizing inventory placement to meet customer demand wherever and however they shop in our store.”

What’s so bad about Macy’s supply chain model?

Customers expect a strong omnichannel experience — one that integrates both the online and offline world of the retailer, enabling a frictionless shopping experience.

For retailers, the goal is to take the retailer’s replenishment cycle from days to hours and reduce inventory at stores. This way, retailers expand their use of stores to fulfil online orders and hold less inventory altogether, allowing them to dedicate more room for digital fulfillment.

Omnichannel shopping is the baseline expectation for customers, as companies such as Gap, Target, and many others have upped their omnichannel game.

And Macy’s is, er, behind.

Macy’s way of viewing their supply chain in the past was traditional: Move products from point A to point B and optimize costs at each stop along the way. Each delivery channel has its own transportation plan and technology stack, siloing all distribution and fulfillment centers.

This supply chain method was acceptable 10 years ago, but to stay afloat in the in-store and online retail spaces, Macy’s needed to make a change. Silos created major cost issues, not to mention slow speed and service in today’s two-day-delivery age.

The company’s supply chain model operated two separate warehouse networks, one for stores and the other for direct customer (online) orders. This system made rebalancing inventory nearly impossible, among other issues.

Macy’s supply chain also lacked a central platform for locating inventory at the SKU level across the chain, and the cost of goods were high compared to competitors since each private brand sold at May’s was sourced independently.

Creating a better supply chain

In 2019 Macy’s hired Dennis Mullahy , the first ever Chief Supply Chain Officer, to transform the supply chain into one that supports an omnichannel strategy.

Since then, Macy’s has made leaps and bounds in optimizing their supply flow, with COVID expediting the process.

The company is transitioning to a centralized warehouse model, implementing a flow and fold design, meaning a light initial allocation to stores and flexible replenishments. Multipurpose warehouses hold inventory, which can both replenish stores and fulfill e-commerce orders.

By having a centralized inventory, the retailer is better able to strengthen its margins and fulfill orders quicker and in the ways customers want.

“Our new model will leverage all of our assets much more productively and improve customer satisfaction by increasing speed of delivery as well as generate efficiencies in our operations and inventory utilization.” Dennis Mullahy wrote.

In addition, Macy’s is getting on board with using data and analytics to not only get items to customers faster, but also improve inventory forecasting and allocation and package consolidation.

The company plans to increase drop-shipping to boost margins in e-commerce, where delivery costs have been the largest drain on profits. They’ll also renew their efforts into Macy’s Backstage operations in order to compete with other off-price companies such as Nordstrom Rack and TJMaxx.

Behind the curve

And while these improvements are giving Macy’s the help it needs, they should’ve seen the warning signs sooner. Retailers of equal size have been making moves to change their supply chain for years now, and Macy’s is just catching up.

For example, Kohls has been working to integrate e-commerce and brick and mortar stores since the beginning of 2018. The company worked to change its purchase and inventory management system by starting with the smallest stores and working their way up.

Nordstrom has been working on omnichannel fulfillment for over 3 years, and brought in tech consulting firm Opex Analytics to help.

Walmart unveiled plans this month to install a high-tech automation system across 25 Walmart regional distribution centers through their partnership with Symbotic, a robotics and automation company — something they’ve been working toward since 2017. This system will digitize and modernize Walmart’s current supply chain facilities to enrich customer experience and support evolving demand.

But even though Macy’s may be a few steps behind, true omnichannel is a journey — and a difficult one at that. It requires a lot from the supply chain, especially in terms of speed, complexity, and efficiency. The global retailer is making strides in executing their Polaris plan by focusing more on the integrated fulfillment strategy and alternative fulfillment options and listening to what their customers want.

Looking for software? Try our IT Product Selection Tool

In this article...

Get FREE Expert Advice

How should our experts reach you?

Learn everything you need to know about Creating an Omnichannel Supply Chain: A Macy’s Case Study. Our experts will reach out to you shortly.

By clicking the button above, I confirm that I have read and agree to the Terms of Use and Privacy Policy.

Supply Chain Management—A Case Study of Huawei’s Supply-Chain Chip Shortage

- Conference paper

- First Online: 08 October 2023

- Cite this conference paper

- Jiangke Chen 7

Part of the book series: Applied Economics and Policy Studies ((AEPS))

Included in the following conference series:

- International Conference on Business and Policy Studies

834 Accesses

Today’s business environment is more competitive and complex. Decreased trade barriers and more developed countries promoting businesses bring more businesses into the market. There is also more competition among organizations because businesses are introducing newer and cheaper innovations at a faster rate Innovation in organizational processes can make significant changes in the product output. Supply chain management is a potential area for technological innovations. Therefore, this paper will focus on the extent to which automation technology and blockchain technology support modern supply chains, and take Huawei as an example to study how Huawei’s global supply chain provides it with a competitive advantage. And makes a study on the current supply chain dilemma faced by Huawei and puts forward feasible solutions. The study found that automation can benefit enterprises by achieving faster and more efficient operations in inventory management and warehouse management. However, enterprises also need to be aware of the high cost of using automation. Blockchain technology can improve supply chain stability and security through smart contracts and shared ledger management. But there are also problems, such as a lack of laws and regulations that reduce the overall efficiency of the supply chain. Huawei’s use of reverse logistics and management of distribution channels have enhanced its supply chain’s competitive edge, but now it faces a chip shortage. For the current Huawei, finding backup suppliers, stabilizing consumer confidence, and maintaining investment in chip research and development are feasible ways to solve the existing problems.

This is a preview of subscription content, log in via an institution to check access.

Access this chapter

- Available as PDF

- Read on any device

- Instant download

- Own it forever

- Available as EPUB and PDF

- Durable hardcover edition

- Dispatched in 3 to 5 business days

- Free shipping worldwide - see info

Tax calculation will be finalised at checkout

Purchases are for personal use only

Institutional subscriptions

Grand View Research. Supply Chain Analytics Market Size, Share & Trends Analysis Report By Solution, By Service, By Deployment, By Enterprise Size, By End Use, By Region, And Segment Forecasts, 2022 – 2030. Published Date: Mar, 2022Report ID: GVR-1–68038–928–9Number of Pages: 170Format: Electronic (PDF)Historical Data: 2017–2020 (2022)

Google Scholar

Statistics. Size of the global supply chain management market worldwide from 2020 to 2026. Global supply chain management market size 2020–2026 | Statista (2022)

Bademosi, F.M., Issa, R.R.: Automation and robotics technologies deployment trends in construction. In: Automation and Robotics in the Architecture, Engineering, and Construction Industry, pp. 1–30. Springer, Cham (2022). https://doi.org/10.1007/978-3-030-77163-8_1

Mehmeti, G., Musabelliu, B., Xhoxhi, O.: The review of factors that influence the supply chain performance. Academic J. Interdisciplinary Stud. 5 (2), 181 (2016)

Li, S., Ragu-Nathan, B., Ragu-Nathan, T.S., Rao, S.S.: The impact of supply chain management practices on competitive advantage and organizational performance. Omega 34 (2), 107–124 (2006)

Article Google Scholar

Eggeling, K.A., Adler-Nissen, R.: The Synthetic Situation in Diplomacy: Scopic Media and the Digital Mediation of Estrangement. Global Studies Quarterly, 1 (2021)

Dash, R., McMurtrey, M., Rebman, C., Kar, U.K.: Application of artificial intelligence in automation of supply chain management. J. Strateg. Innov. Sustain. 14 (3), 43–53 (2019)

Christiansen, L.: The Top Disadvantages of Business Process Automation. Available at: The Top Disadvantages of Business Process AutomationMenu (altametrics.com) (2020)

Kolokotronis, N., Limniotis, K., Shiaeles, S.N., Griffiths, R.: Blockchain Technologies for Enhanced Security and Privacy in the Internet of Things. ArXiv, abs/1903.04794 (2019)

Hooper, A., Holtbrügge, D.: Blockchain technology in international business: changing the agenda for global governance. Review of International Business and Strategy (2020)

Honeywell. Supply Chain (2022). https://www.honeywell.com/us/en/industries/supply-chain

Litan, A., Reynolds, M., Jones, L.C.: Managing the Risks of Enterprise Blockchain Smart Contracts. Published: 24 February 2020 ID: G00465806 (2020)

Karlborg, A.: Huawei Reverse Strategy under Circular Economy (2020). https://www.bing.com/ck/a?!&&p=a132e3eead3967160292f7d7651f5fbad9a9b3f0920198caa6c58c7d380475c4JmltdHM9MTY1NDI1MzI0MCZpZ3VpZD0zNTIzMGE3YS0zNDExLTRlODUtYjFmZi05MTFlMzEzODk3NzAmaW5zaWQ9NTE4Mg&ptn=3&fclid=8ab814b6-e32a-11ec-9396-d2fb28130597&u=a1aHR0cHM6Ly93d3cuaXR1LmludC9lbi9JVFUtVC9Xb3Jrc2hvcHMtYW5kLVNlbWluYXJzL2dzdy8yMDE0MDYvRG9jdW1lbnRzL1ByZXNlbnRhdGlvbnMvRm9ydW0tb24tRXdhc3RlLTIzLTA5LTIwMTQvUHJlczAxLUFuZGVyc0thcmxib3JnLUUtV2FzdGUtR1NXMjAxNC1PcGVuaW5nQ2VyZW1vbnkucGRm&ntb=1

Sajadieh, M.S.: Global Supply Chain Management. In: Zanjirani Farahani, R., Asgari, N., Davarzani, H. (eds) Supply Chain and Logistics in National, International and Governmental Environment. Contributions to Management Science. Physica-Verlag HD (2009). https://doi.org/10.1007/978-3-7908-2156-7_3

Thongyod, S.: The Strategic Analysis of Huawei Investment & Holding Co., Ltd. MGN512 - Strategic Management. Third Semester, Academic Year 2018 Master of Business Administration, Stamford International University (2019)

Cole, R., Aitken, J.: ‘The role of intermediaries in establishing a sustainable supply chain’. J. Purchasing and Supply Manage. 26 (2) (2020). https://doi.org/10.1016/j.pursup.2019.04.001

Gaille, B.: 12 Pros and Cons of Distribution Channels. 12 Pros and Cons of Distribution Channels - BrandonGaille.com (2015)

Williams, R.D., Center, P.T.C.: Beyond Huawei and TikTok: Untangling US Concerns Over Chinese Tech Companies and Digital Security (2020)

Mcdonald, J.: Huawei revenue sinks as smartphones hurt by US sanctions. Huawei revenue sinks as smartphones hurt by US sanctions - ABC News (go.com) (2021)

Berning, S.C.: The role of multinational enterprises in achieving sustainable development-the case of Huawei. European J. Sustainable Dev. 8 (3), 194 (2019)

Download references

Author information

Authors and affiliations.

School of Management Science, CDUT Sino-British Collaborative Education, Chengdu, 610059, China

Jiangke Chen

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to Jiangke Chen .

Editor information

Editors and affiliations.

King's Business School, King's College London, London, UK

Canh Thien Dang

Department of Financial Economics and Accounting, University of Murcia, Murcia, Spain

Javier Cifuentes-Faura

Department of Postal Management, Beijing University of Posts and Telecommunications, Beijing, China

Xiaolong Li

Rights and permissions

Reprints and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper.

Chen, J. (2023). Supply Chain Management—A Case Study of Huawei’s Supply-Chain Chip Shortage. In: Dang, C.T., Cifuentes-Faura, J., Li, X. (eds) Proceedings of the 2nd International Conference on Business and Policy Studies. CONF-BPS 2023. Applied Economics and Policy Studies. Springer, Singapore. https://doi.org/10.1007/978-981-99-6441-3_3

Download citation

DOI : https://doi.org/10.1007/978-981-99-6441-3_3

Published : 08 October 2023

Publisher Name : Springer, Singapore

Print ISBN : 978-981-99-6440-6

Online ISBN : 978-981-99-6441-3

eBook Packages : Political Science and International Studies Political Science and International Studies (R0)

Share this paper