Running an Aircraft Manufacturing Company – Tips for Success

- Establish a clear vision and a realistic business plan for your aircraft manufacturing company.

- Source quality materials and maintain a good inventory, including efficient storage units for aircraft parts.

- Attract and retain skilled employees through competitive benefits, training, and career development opportunities.

- Foster strong customer relationships through quick response, quality support, rewards, and keeping them informed.

- Ensure good financial control for better tracking of performance indicators and profitability in your company.

Running an aircraft manufacturing company is no easy feat. From developing the design to managing employees, production, and customer relationships, producers face several challenges. However, you can succeed and thrive in this industry with the right approach and mindset. This blog will share essential tips for running an aircraft manufacturing company successfully.

Develop a Clear Vision and Stick to It

To run a successful aircraft manufacturing company, you must have a clear vision of what you want to achieve and how to get there. You need to set realistic and achievable goals, establish a long-term plan, and ensure everyone in your organization is on the same page.

Ensure your plans and vision are firm and constantly reviewed and refined so everyone knows what is expected of them. Having a vague idea of what you want isn’t enough. Successful businesses start with a clear focus and a thorough and realistic business plan.

Source Quality Materials

When producing aircraft, you need to source quality materials and components. This will ensure the craft is made with precision and safety measures in mind. Do your research into reputable suppliers and make sure you have a good inventory of parts so you can respond quickly to customer orders.

It’s also important to remember that your aircraft’s components aren’t the only quality materials you need to source. Even something small, like the storage units for your aircraft parts, can make all the difference. Invest in good quality aircraft parts storage units so your parts are organized and accessible when you need them. These storage units can also be customized to fit the exact size and needs of your particular aircraft.

Attract and Retain Talented Employees

Employees are at the heart of any successful company. To produce the best aircraft, you need skilled and experienced employees who are passionate about their work. Make sure to put in place a competitive benefits package like healthcare, retirement plans, and bonuses that keep your employee motivated and encourage them to stay with your company for the long term. Offer training and career development opportunities to help keep your employees growing both professionally and personally.

Build Strong Customer Relationships

One of the core features of a successful aircraft manufacturing company is having satisfied customers. They not only bring repeat business but also spread the good word about your products and services, which can bring new customers to you. To ensure you have satisfied customers, build a strong relationship with them. Here are four ways you can achieve this:

Respond to customer queries quickly.

Responding to customer queries quickly will show them that you value their time and opinion, which can help build trust. You can do this by setting up a customer service system that responds to queries quickly and efficiently.

Provide quality support.

Providing excellent customer support is vital for keeping customers satisfied. This includes responding to their issues promptly and helping them resolve any problems they may have with your products or services.

Offer rewards and discounts.

Rewarding loyal customers with discounts or exclusive offers can encourage them to continue doing business with your company. You can also reward customers for referring friends or family members, which can help spread your reputation and reach.

Keep them informed.

Keep customers updated about changes in your products and services, such as new features or updates that they can benefit from. This will make them feel valued as you are keeping them informed about what’s going on in your company.

By building solid relationships with your customers, you can ensure they remain satisfied and come back to you in the future.

Maintain Strong Financial Control

The last tip for succeeding in aircraft manufacturing is maintaining good financial control. Financial control helps you track key performance indicators, minimize waste, and measure profitability.

With good accounting and finance systems, you can identify inefficiencies and invest resources intelligently to achieve your goals. You may consider getting professional help to maintain and prepare your financial statements.

Running a successful aircraft manufacturing company requires a clear vision, sourcing quality materials, attracting and retaining talented employees, building strong customer relationships, and maintaining strong financial control.

These are not easy tasks, but your company can thrive in this competitive industry by committing to these principles. Remember that every step, no matter how small, is a step towards achieving your goal. Stay focused on your vision, remain adaptable, and strive for excellence.

About The Author

Sophie Reed

Start typing and press enter to search.

- Search Search Please fill out this field.

The Airplane Manufacturing Market

Top aircraft manufacturers, the bottom line.

- Fundamental Analysis

- Sectors & Industries

Who Are the Major Airplane Manufacturing Companies?

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master's in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

:max_bytes(150000):strip_icc():format(webp)/adam_hayes-5bfc262a46e0fb005118b414.jpg)

Katrina Ávila Munichiello is an experienced editor, writer, fact-checker, and proofreader with more than fourteen years of experience working with print and online publications.

:max_bytes(150000):strip_icc():format(webp)/KatrinaAvilaMunichiellophoto-9d116d50f0874b61887d2d214d440889.jpg)

Although the airline industry is highly competitive, the competition among aircraft suppliers is relatively limited. Lesser-known makers of large passenger airplanes are attempting to build a more significant presence on the world's stage. Still, in the large commercial aircraft market, there are just two major players: the U.S.-based Boeing ( BA ) and the Airbus Group ( EADSY ), formerly known as the European Aeronautic Defense and Space Company (EADS).

Key Takeaways

- The global airplane manufacturing market is valued at over $400 billion.

- The world's only major large passenger aircraft manufacturers are Boeing and Airbus.

- Boeing's and Airbus's established jet brands are the 7-series and A-series, respectively.

- Up-and-coming large passenger airplane makers include Comac in China, Mitsubishi in Japan, and UAC in Russia.

- Based on deliveries, Airbus takes the top spot as the largest airplane manufacturer in the world.

Airbus is the world's top commercial airplane manufacturer based on airplanes delivered. Boeing is in second place, as its deliveries stalled because of the grounding of certain aircraft, the COVID-19 pandemic, and issues for its 737-MAX aircraft.

The airplane manufacturing market is part of the overall airline industry. The global market's estimated value was more than $400 billion in 2023, and is expected to grow to more than half-a-trillion dollars by 2029. Companies in this market are involved in the manufacturing of airplanes and their components, including engines and propulsion systems.

Large passenger airplane manufacturers

Boeing and Airbus are the world's only major large passenger aircraft manufacturers. The two companies share almost exclusive control of the worldwide airplane supply business for large commercial jets. Their established brands are Boeing's 7-series and Airbus's A-series of jets. These aircraft include narrow-body aircraft, wide-body aircraft, and jumbo jets.

Regional and other international airplane manufacturers

Bombardier, based in Canada, and Embraer, a Brazilian aircraft manufacturer, are leaders in the regional and business airplanes market. They both focus on smaller-sized jets.

On a global scale, competition with Boeing and Airbus is brutal. However, newer airline suppliers Comac in China, Mitsubishi in Japan, and UAC in Russia are working on a series of new wide-body jets in a joint venture . They hope to eventually become a legitimate competitor that can take on the dominance of Boeing and Airbus in the large-jet space.

Military airplane manufacturers

Boeing and Airbus have a significant market share in the supply of military aircraft, particularly in the U.S. Their competition in this market includes Lockheed Martin. Just under half of Boeing's revenues came from U.S. government contracts in 2022. Only about 20% of Airbus' revenues came from defense contracts in 2022.

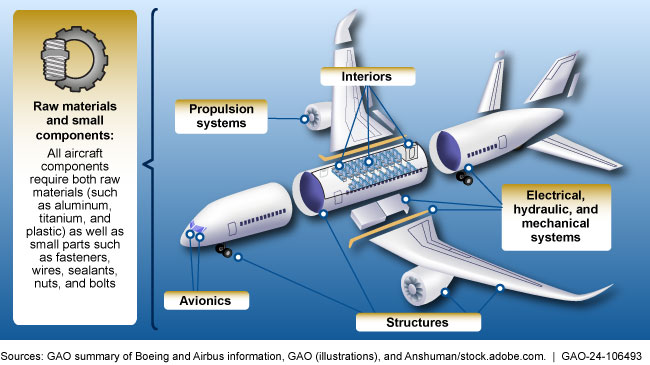

Suppliers to airplane manufacturers

Aerospace suppliers are critical to the aircraft manufacturing ecosystem. They provide essential components, systems, and materials required to build an aircraft. This includes avionics, propulsion systems, landing gear, cabin interiors, and composite materials. These suppliers range from large companies that produce major systems to smaller specialized firms. Aircraft manufacturers rely on these suppliers for the initial construction of aircraft and ongoing maintenance and replacement parts.

Raytheon Technologies Corporation ( RTX ) and General Electric ( GE ) are two major companies that manufacture airplane engines and other parts for industry operators. Rolls-Royce ( RYCEY ), Pratt & Whitney, and Honeywell ( HON ) also produce airplane jet and propeller engines.

Here are some of the largest aircraft manufacturers in the world. All data as of Q1 2024.

Boeing (BA)

- Headquarters : Chicago, Illinois, USA

- Founded : 1916

- Market Cap : $130 billion

- Employees : 156,000

- Products : Known for manufacturing a wide range of commercial jetliners, Boeing's product line includes the 737, 747, 767, 777, and 787 families of airplanes. The company also offers military aircraft, satellites, and other aerospace products and services .

Once the darling of the aircraft business, Boeing has faced some critical challenges recently, most notably issues related to the safety of its aircraft. Incidents involving the 737-MAX's in-flight controls and aircraft doors detaching midflight have raised serious concerns. These issues have not only affected Boeing's reputation and financial stability but also have wider implications for airline safety standards and consumer confidence in the industry.

Airbus (EADSY)

- Headquarters : Leiden, Netherlands

- Founded : 1970

- Market Cap : $128.6 billion

- Company Size : 134,000

- Products : Airbus is known for its commercial aircraft, including the A220, A320, A330, A350, and A380 families. The company also produces military planes and helicopters and provides aerospace-related services.

Lockheed Martin (LMT)

- Headquarters : Bethesda, Maryland

- Founded : 1995 (from the merger of Lockheed Corporation and Martin Marietta)

- Market Cap : $113.6 billion

- Employees : 116,000

- Products : While focused on defense and military aircraft , such as the F-16 and F-35 Lightning II, Lockheed Martin also engages in aeronautics, missiles, fire control, and space systems.

Embraer (ERJ)

- Headquarters : São Paulo, Brazil

- Founded : 1969

- Market Cap : $3.2 billion

- Employees : 18,000

- Products : Embraer is known for its E-Jet and E-Jet E2 series of regional jets, popular among airlines for short to medium-haul flights.

Boeing comes in second as the largest airplane manufacturer in the world because of manufacturing problems that led the Federal Aviation Administration (FAA) to halt deliveries of its 787 model.

Bombardier (BDRBF)

- Headquarters : Montreal, Quebec, Canada

- Founded : 1942

- Market Cap : $3.7 billion

- Employees : 15,000

- Products : The company's aerospace division is known for its business jets, including the Challenger and Global series.

How Are New Aircraft Certified to Fly?

Aircraft certification is a rigorous and detailed process conducted by aviation authorities such as the FAA in the U.S. or the European Union Aviation Safety Agency (EASA) in Europe. This process involves extensive testing and evaluation of the aircraft's design, construction, and performance to ensure it meets strict safety standards. It includes analysis of the airframe, engines, systems, and flight performance, with assessments of the aircraft's handling under various conditions.

How do market dynamics between Boeing and Airbus influence the airplane manufacturing industry?

The duopoly of Boeing and Airbus significantly influences market dynamics in the airplane manufacturing industry. Their competition is legendary, driven by their high-stakes duopoly, the need to stay ahead in avionics and other changing technology, and the geopolitics around Boeing being a major American company and Airbus being a European consortium. As manufacturing for other goods had for decades been moving out of Europe and the U.S., these two companies were also emblems of what the U.S. and Europe could still produce.

Court battles, World Trade Organization complaints, and negotiations at the highest political levels for aircraft contracts mean more is at stake than simply any new plane put out by one requires an answer from the other. Together, this duopoly's decisions on production rates, aircraft models, and what technology they will use set trends for the entire industry, affecting everything from airline fleet choices to what kind of technology pilots and regular consumers will find once on board.

How Did the COVID-19 Pandemic Impact Aircraft Manufacturers?

The COVID-19 pandemic significantly impacted the aircraft manufacturing industry. There was a drastic cut in demand for new aircraft because of the sudden decline in air travel. This led to production slowdowns, delays in aircraft deliveries, and financial challenges for manufacturers. However, the industry has been adapting by focusing on more flexible manufacturing processes, increasing cargo aircraft production because of the rise in ecommerce and accelerating digital transformation to improve efficiency.

The airplane manufacturing market, valued at over $400 billion, is a significant part of the global airline industry, which is expected to grow considerably over the next decade. Dominated by Boeing and Airbus, the only major manufacturers of large commercial jets, this market is characterized by their iconic 7x7-series and A3xx-series jets. Suppliers, including GE, Raytheon Technologies, and Rolls-Royce, are pivotal in providing essential components like engines and avionics. While facing lingering challenges from the COVID-19 pandemic leading to reduced demand and production, the industry is adapting through flexible manufacturing and other changes. Boeing, in particular, has encountered significant mechanical challenges with its 737-MAX and 787 models, affecting its position in the global market.

Precedence Research. " Aircraft Manufacturing Market Size Global Report, 2023-2032. "

The Boeing Company. " 2022 Annual Report. "

Airbus. " Financial Results and Annual Report ."

Raytheon Technologies. " United Technologies and Ratheon Complete Merger of Equals Transaction. "

Companies Market Cap. " Top Aircraft Companies - Employees ."

Economic Times . " Boeing’s Legacy Vanished Into Thin Air and Saving It Will Take Years ."

Airbus. "Who We Are"

Lockheed Martin. "Who We Are"

Embraer.com. "About Us"

Federal Aviation Administration. " Airworthiness Certification ."

Ayoung Woo, et al. " An Analysis of the Competitive Actions of Boeing and Airbus in the Aerospace Industry Based on the Competitive Dynamics Model ." Journal of Open Innovation: Technology, Market, and Complexity . 7,.3 (2021).

McKinsey & Co. " COVID-19's Impact on the Global Aviation Sector ."

:max_bytes(150000):strip_icc():format(webp)/fast-fashion-6d4aa773355b42c69c545bef9c9747a1.jpg)

- Terms of Service

- Editorial Policy

- Privacy Policy

Start an Aircraft Manufacturing Business

- 37 comments

- 2 expert advice

- 26,540 views

Far from the common scenario in the past, there are already lots of people who embrace aircraft services, especially if they want to go from one place to another.

- Google Share

This means that people who want to open different kinds of venture can already start an aircraft manufacturing business.

Since aircraft manufacturing might seem to be a complex venture, it is important that you know some information about the matter first. If you are looking for information on how to start aircraft manufacturing business, this article will provide you the things you need to know.

Business Research

Since this might be new to you, it is important that you keep yourself informed of what the business is. This means that you should conduct research in order to orient yourself regarding what it is all about. Basically, you can search for some sites in the internet related to the matter but it is always better if you have substantial period of working experience from the same field. These sites can provide you valuable information to understand the nature of the business deeper. Furthermore, you can also ask other business owners running the same venture in order to know valuable facts about this type of business.

Create Business Plan

First and foremost, people who want to start aircraft manufacturing business should begin actualizing their dream venture by simply creating business plan. The business plan serves as the Bible of your business. This means that it provides guidance on the entire path of your aircraft manufacturing business. Keep in mind that there are important components you should focus on in creating your business plan. Examples of these are:

- General Business Overview

- Goals and Objectives

- Description of Products Offered

- Analysis and Study of the Target Market

- Marketing Strategies to be Used

Legalizing the Business

After the development of strong and concise business plan, the next thing you need to do is to legalize your business. There are some requirements you need to secure in order to legalize your business. All you just need to do is to go to the concerned business licensing agencies and departments in your place to know more about the matter. Of course, the most basic requirement in legalizing your business is applying for a business permit. This might take some time and require you some money. However, this will be all worth it in the end.

Facilities, Location and Staff

To start an aircraft manufacturing business, it is important to consider facilities, location and staff. In terms of facilities, there are machineries you need to use in the future to make this business possible. When it comes to location, choose the best place where you can establish your business. The place should have enough size and is accessible on your part. In addition to that, look for staff that has technical skills regarding aircraft manufacturing. See to it that your staff is also hard working, dedicated to their work and is willing to help you grow your business.

37 Comments

- Ramkumar patne said on January 9, 2013 Hello i'm Ramkumar. i was a students of aeronautical engineering in delhi (INDIA). i have passed three license in AME field. i want to start aircraft manufacturing business in MADHYA PRADESH (INDIA). Plz guide me and tell me about requirement

- Sajjad said on August 21, 2013 @Ramkumar patne, I assume you've just completed your studies so I doubt that you would have much cash with you at this stage of life. Starting a simple aircraft manufacturing business would need an immediate injection of at least $500m.

- Isaac said on February 21, 2014 When you are talking of a simple aircraft manufacturing business and that you need $500 millions to open it, how simple is the business your talking about?

- James said on July 1, 2014 I have a new jet design that will need venture capital not to exceed $20M. Are there other focus areas you would suggest for this type of plan, other than what you have listed?

- Bereket said on July 17, 2014 Are u serious $500m to start up an aircraft manufacturing business. Is worth it??

- pintu sharma said on August 5, 2014 I want to start a two sitter air craft company . Now I am running heavy mechanical job company myself.

- m.sandeep said on August 18, 2014 hi my name is sandeep and i am in aero 2 year. i have only 10 lakhs of money so i want to start air craft manufacturing company in my state and i will provide more jobs to my people so .if any bank or government providing any loan plz tell me about that sir

- yathish kumar said on September 4, 2014 any one can let me know the procedure to start up a new aircraft manufacturing industry.

- Arya Dharmpal Chandresh said on September 15, 2014 I want to manufacturing of Aircraft products in jaipur please suggest me.

- Nimod K.A. said on October 28, 2014 I have a dream of starting an aircraft manufacturing company which will manufacture passenger aircrafts. I have no money with me, but if there are people ready to invest, I am sure I can quit my job and work on this mission. Currently 10 countries have aircraft manufacturing companies which manufacture passenger aircraft and sadly India is not among them. Also linked with 'Make in India' move, I invite people who can support me in this...

- varun jayavelu said on February 27, 2015 @nimod i am interested in your idea of manufacturing passenger aircraft but initially manufacturing paramotors and trikes would be cheaper.

- Alex martinez said on April 8, 2015 Wichita,Kansas USA. I am looking for information in starting up a small assembly shop in the aircraft industry. I know someone who worked at Censa for 20 years, currently is assembling a part for Censa. They have tried to outsource his job to Mexico but they failed. He and I are looking to start up a small Shop and have the correct certification to assembly the part. I know we will need an as 9100 certification that will be for the mechanic but what certification will the inspector need?

- Jose Bay Grajeda said on July 1, 2015 I'm thinking in starting an aerial company ... but how do you start out? coming out of college keeps you pretty broke, so how do i start a business when i have no money to buy the equipment and staff? Please Help!!!

- Boeing international said on July 13, 2015 Love to see that many people wants to open there know aircraft company. Today there are lots of company to boost your company name you should come up with new idea like small jet plane, or solar plane or light weight plane. You should have at least $10 million to start and buy equipments for your dream plane.

- gaurav said on February 1, 2016 Friends i have also same dream as u all have but their is problem of investor with all of us so we can achieve our dream if we work together [email protected] .....guys i know we have fire in our hearts and if we work together we will definitely.....find a way to start this....plz all who r interested msg me on my email id or my watsap no. 9917429225

- Ankur Kamboj said on March 6, 2016 Hi @gaurav , I too have same intentions with lot of energy and interest . Please check your mail. I will encourage other interested persons to share or contact as well.

- vishal said on April 3, 2016 9462588411

- vishal said on April 3, 2016 i want to open myths own aircraft and helecopter company... so u guide me cantact me.. 9462588411

- jaipal kethavath said on April 4, 2016 i have an ultralight aircraft design that i prepaid. so i have also same intention to start a/c man comp.

- Vinod Malshikare said on May 4, 2016 Dear friends, I am vinod malshikare from India. I want to strting new and modern models of aircraft which will be making at least cost and gives best performance. so I will start when a person who guide me perfectly. If any one can help me then please contact mi [email protected] please leave message.

+2348065134393 || [email protected] || Aircraft Manufacturing Expert

- TANAKA MAKUNI said on September 18, 2016 @Jaipal @vishal and EVERYONE .You seem to be anxious and enthusiastic in venturing into this business like everyone else here, so I propose working together. Contact me on whatsapp and maybe we can share ideas, help each other make this a reality. +263773999952

- ranganathan said on November 14, 2016 alright I THINK first we need to focus on the model of the aircraft company and find its estimation and then start all around. then how do we get the raw materials and the scope of the industry in our country. where do i get the information regarding about all that? where do i get the money from? how do i arrange the such huge fund? are there banks to support this? what steps to take in finding it? then where do i find the buyers of my products? are there good HR who can do pretty well in our field in our country? how to get the guidance from the business leaders? how do i startup? plz do contact me ph:9741168215

- DEEPAK KUMAR UPADHYAY said on November 28, 2016 I want to start my own manufacturing plant for aircraft .. kindly suggest me friends, and team from entire world who are interested in same kindly contact me .. email id: [email protected], contact number: +91-7839272383

- Deepak said on December 1, 2016 I want to start my own manufacturing plant for aircraft .. kindly suggest me friends, and team from entire world who are interested in same kindly contact me .. email id: [email protected] contact number: +91-9781940114

[email protected] || Aircraft Industry Adviser

- Ibra Rilz Kasasa. said on January 8, 2017 Hi, am Ibra Rilz in Uganda. Am also interested in aircraft manufacturing. I don't have any money with me now, am in high school. But am sure i have some skills especially the engine, wings and even fuel or gas production. Those who want to start up any aeroplane making business can contact me, i assure that am dedicated and determined and will work to the success of the business.

- premkumar said on March 18, 2017 I am premkumar ame student atjawaharlal aviation institute pala skkad kerala i also have the same dream of starting a microlight aircraft company in kerala but i dont have money or investors for my dream share your valuable ideas to my mail premkumar [email protected]

- ojaskar said on April 13, 2017 i am a indian i also have a dream to start air craft company

- Arush Khjuriya said on January 14, 2018 We Can Make a Whatsapp Group and discuss ideas +91 9911964706

- Rukundo Enock said on January 27, 2018 I am a 20 year old Ugandan on ky way to starting an aircraft manufacturing business

- Vinod said on June 28, 2019 All start-up members plz comments on whats app no. I am starting a group

- oyibe matthew said on September 28, 2019 my name oyibe Matthew. i am a nigerian please I want to start an aircraft manufacturing company. But I don't know how to start. I have some ideas for the name, the investors i know the model of aircraft ideas, and other things. please let us make a team [email protected] and umdolmal [email protected]

- Roger Port said on November 25, 2019 I've been trying to get $10 mill funding for a startup here in the U.S., preferably the majority ($7-8 mil) and the rest from banks ($2-3 mil). We currently have 4 prototypes built that fly, and are certified by the F.A.A. We have almost everything needed to start, except the capital to start. Any help would be appreciated. [email protected]

- Ed Rij said on September 23, 2020 Roger, Have you had any luck in finding funding for your prototypes? Send me some information on your aircraft.

- Malik said on July 12, 2023 I'm planning to have a company..so we need a team... Then we can look for funds. My WhatsApp is +63 905 455 5570. Email: [email protected]

- Mr. MerMan said on December 18, 2023 All you guys talking about manufacturing aircraft without any money are stupid

- Franchise Opportunities

- Wholesale Business Opportunities

- Small Manufacturing Business

- Farming Business Ideas

- Unique Business Opportunities

- Shop Business Ideas

- Small Business Opportunities

- Startup Company Ideas

- Home Based Business Opportunity

- Rural Business Opportunities

- Tips for Buying and Selling

- Starting Rental Business

- Ideas for Small Business

- Free Business Ideas

- Internet Business Ideas

- Store Business Opportunities

- Entrepreneur Business Idea

- Retail Store Ideas

- Service Business Ideas

- Advice for Small Business

- Financing a Small Business

- Restaurant Business Opportunities

- Small Business Articles

- Business Marketing and Advertising

- Repair Business Opportunity

- Professional Career Opportunities

- Business Insurance Information

- Instructor Guides

Popular Articles

- About Pharmaceutical Manufacturing Business

- Starting a Plastic Manufacturing Plant

- Becoming a Brick Manufacturer

- Setting up an Animal Feed Manufacturing Company

- Starting a Garment Manufacturing Business

- Startup Guide for Chemical Manufacturing Business

- Starting Tobacco Product Manufacturing Company

- Glass Manufacturing Business

- Start Diaper Manufacturing Business

- Top 5 Money Making Manufacturing Businesses to Start in South Africa

Free Download

Aircraft Equipment Maker Business Plan Template

Download this free aircraft equipment maker business plan template, with pre-filled examples, to create your own plan..

Or plan with professional support in LivePlan. Save 50% today

Available formats:

What you get with this template

A complete business plan.

Text and financials are already filled out and ready for you to update.

- SBA-lender approved format

Your plan is formatted the way lenders and investors expect.

Edit to your needs

Download as a Word document and edit your business plan right away.

- Detailed instructions

Features clear and simple instructions from expert business plan writers.

All 100% free. We're here to help you succeed in business, no strings attached.

Get the most out of your business plan example

Follow these tips to quickly develop a working business plan from this sample.

1. Don't worry about finding an exact match

We have over 550 sample business plan templates . So, make sure the plan is a close match, but don't get hung up on the details.

Your business is unique and will differ from any example or template you come across. So, use this example as a starting point and customize it to your needs.

2. Remember it's just an example

Our sample business plans are examples of what one business owner did. That doesn't make them perfect or require you to cram your business idea to fit the plan structure.

Use the information, financials, and formatting for inspiration. It will speed up and guide the plan writing process.

3. Know why you're writing a business plan

To create a plan that fits your needs , you need to know what you intend to do with it.

Are you planning to use your plan to apply for a loan or pitch to investors? Then it's worth following the format from your chosen sample plan to ensure you cover all necessary information.

But, if you don't plan to share your plan with anyone outside of your business—you likely don't need everything.

More business planning resources

How to Write a Business Plan for Investors

Business Plan Template

How to Start a Business With No Money

Industry Business Planning Guides

10 Qualities of a Good Business Plan

How to Write a Business Plan

Simple Business Plan Outline

How to Create a Business Plan Presentation

Download your template now

Need to validate your idea, secure funding, or grow your business this template is for you..

- Fill-in-the-blank simplicity

- Expert tips & tricks

We care about your privacy. See our privacy policy .

Not ready to download right now? We'll email you the link so you can download it whenever you're ready.

Download as Docx

Download as PDF

Finish your business plan with confidence

Step-by-step guidance and world-class support from the #1 business planning software

The quickest way to turn a business idea into a business plan

Fill-in-the-blanks and automatic financials make it easy.

No thanks, I prefer writing 40-page documents.

Discover the world’s #1 plan building software

Business Plan Template for Aviation Industry Professionals

- Great for beginners

- Ready-to-use, fully customizable Subcategory

- Get started in seconds

Ready for takeoff in the aviation industry? ClickUp's Business Plan Template for Aviation Industry Professionals is your flight plan to success!

Designed specifically for aviation industry professionals like you, this template will help you:

- Outline your company's goals, strategies, and financial projections with ease

- Communicate your vision to potential investors, airline executives, or other stakeholders

- Secure financing or support for your aviation-related business endeavors

Whether you're starting a new airline, launching an aviation technology startup, or looking to expand your existing aviation business, this template has everything you need to soar above the competition. Get started now and watch your dreams take flight!

Business Plan Template for Aviation Industry Professionals Benefits

When it comes to the aviation industry, having a solid business plan is crucial for success. With ClickUp's Business Plan Template for Aviation Industry Professionals, you can enjoy the following benefits:

- Clearly articulate your business goals and strategies, helping you stay focused and on track

- Showcase your expertise and industry knowledge to potential investors or partners

- Create compelling financial projections that demonstrate the profitability and viability of your aviation venture

- Streamline the process of securing financing or support by providing a comprehensive and professional business plan specific to the aviation industry

Main Elements of Aviation Industry Professionals Business Plan Template

Planning your aviation business has never been easier with ClickUp’s Business Plan Template for Aviation Industry Professionals. Here are the main elements you can expect from this template:

- Custom Statuses: Track the progress of each section of your business plan with statuses like Complete, In Progress, Needs Revision, and To Do.

- Custom Fields: Add important details such as Reference, Approved, and Section to ensure your business plan is comprehensive and well-organized.

- Custom Views: Access five different views, including Topics, Status, Timeline, Business Plan, and Getting Started Guide, to easily navigate and manage your aviation business plan.

- Collaboration Tools: Collaborate with your team in real-time, assign tasks, set due dates, and leave comments to ensure everyone is on the same page.

- Document Management: Attach relevant files, such as financial projections or market research, to keep all your important documents in one place.

- Goal Tracking: Set specific goals and milestones for your aviation business and track progress using ClickUp’s Goals feature.

With ClickUp’s Business Plan Template for Aviation Industry Professionals, you can create a comprehensive and visually appealing business plan to propel your aviation venture to new heights.

How To Use Business Plan Template for Aviation Industry Professionals

If you work in the aviation industry and need to create a business plan, the Business Plan Template in ClickUp can help you get started. Follow these six steps to create a comprehensive plan for your aviation business:

1. Define your business concept

Begin by clearly articulating your business concept. What services or products will your aviation business offer? Who is your target audience? What makes your business unique? Answering these questions will help you establish a clear vision for your business.

Use the Docs feature in ClickUp to outline your business concept and brainstorm ideas.

2. Conduct market research

To create a successful business plan, you need to understand the aviation industry and your target market. Research your competition, identify industry trends, and analyze the needs and preferences of your potential customers.

Utilize the Table view in ClickUp to organize and analyze your market research data.

3. Develop a marketing strategy

Your business plan should include a comprehensive marketing strategy to attract customers and generate revenue. Determine the most effective marketing channels for reaching your target audience, establish your brand identity, and outline your pricing and promotion strategies.

Create tasks in ClickUp to outline your marketing tactics and assign responsibilities to team members.

4. Outline your operational plan

In this section, define how your aviation business will operate on a day-to-day basis. Include information about your facilities, equipment, staffing requirements, and operational processes. Consider factors such as maintenance, safety protocols, and regulatory compliance.

Use the custom fields feature in ClickUp to track key operational details and ensure everything is accounted for.

5. Develop a financial plan

A solid financial plan is crucial for the success of any business. Determine your startup costs, projected revenue, and expenses. Create a budget, forecast your financial performance, and identify potential funding sources.

Utilize the Gantt chart feature in ClickUp to create a timeline for your financial projections and track your progress.

6. Monitor and review

Once your business plan is complete, regularly monitor and review your progress. Keep track of key performance indicators, revisit and update your goals, and make adjustments as needed. Regularly reviewing your business plan will help you stay on track and adapt to changes in the aviation industry.

Set up recurring tasks and reminders in ClickUp to ensure that you regularly review and update your business plan.

By following these steps and utilizing the Business Plan Template in ClickUp, you can create a comprehensive and effective business plan for your aviation industry business.

Get Started with ClickUp’s Business Plan Template for Aviation Industry Professionals

Aviation industry professionals can use this Business Plan Template for the Aviation Industry to effectively communicate their vision and secure financing or support for their aviation-related business endeavors.

First, hit “Add Template” to sign up for ClickUp and add the template to your Workspace. Make sure you designate which Space or location in your Workspace you’d like this template applied.

Next, invite relevant members or guests to your Workspace to start collaborating.

Now you can take advantage of the full potential of this template to create a comprehensive business plan:

- Use the Topics View to outline the key sections and topics of your business plan

- The Status View will help you track the progress of each section and topic, with statuses such as Complete, In Progress, Needs Revision, To Do

- Utilize the Timeline View to create a visual representation of your business plan's timeline and milestones

- The Business Plan View provides a holistic view of your entire business plan, allowing you to easily navigate and review each section

- Use the Getting Started Guide View to provide a step-by-step guide for others to follow when reviewing or implementing your business plan

- Customize the Reference, Approved, and Section custom fields to add additional information and categorize your business plan sections

- Update statuses, custom fields, and progress as you work through each section to keep stakeholders informed of progress

- Monitor and analyze your business plan to ensure it aligns with your goals and objectives.

- Business Plan Template for Casino Employees

- Business Plan Template for Materials Scientists

- Business Plan Template for Business Owners

- Business Plan Template for Online Business Owners

- Business Plan Template for Energy Providers

Template details

Free forever with 100mb storage.

Free training & 24-hours support

Serious about security & privacy

Highest levels of uptime the last 12 months

- Product Roadmap

- Affiliate & Referrals

- On-Demand Demo

- Integrations

- Consultants

- Gantt Chart

- Native Time Tracking

- Automations

- Kanban Board

- vs Airtable

- vs Basecamp

- vs MS Project

- vs Smartsheet

- Software Team Hub

- PM Software Guide

StartupBoeing

Prepare for takeoff.

Starting an airline is tough. Running a profitable airline is even tougher. From startup airlines to established industry leaders, the process involves constant learning and adaptation.

Few businesses have as many variables and challenges as airlines. They are capital-intensive. Competition is fierce. Airlines are fossil fuel dependent and often at the mercy of fuel price volatility. Operations are labor intensive and subject to government control and political influence. And a lot depends on the weather.

But the intrepid entrepreneur is not alone. The StartupBoeing team assists entrepreneurs in launching new airlines. From concept through launch, StartupBoeing offers guidance, review, analysis, data, resources, contacts, and referrals to qualified startup airlines.

For further questions or dialogue, please e-mail us at [email protected] .

Market Analysis

Entrepreneurs who are considering a startup airline launch are wise to study the commercial aviation market. Three comprehensive publications are very useful in providing a detailed analysis of traffic growth, regional trends, and airplane requirements. They are produced by Boeing and highly regarded throughout the industry.

Commercial Market Outlook World Air Cargo Forecast Current Aircraft Finance Market Outlook

Operating Environment

Startup airlines must be aware of and operate within a framework of regulations, standards and guidelines. Included here is basic information on some of the primary international agreements and programs that shape the operating environment for commercial aviation.

Learn about the " Freedoms of the Air ," a set of international rights that allow a country's airlines to enter the airspace of another country or land there.

Find out more about ETOPS , or Extended Operations, a collaborative industry/government program allowing airplanes to fly routes with longer diversion times.

Business Planning

Successful startup airlines begin with a sound business plan. This detailed planning document typically includes:

- Analysis of the market and competition

- Brand positioning

- Description of the business and opportunity

- Details about the operation

- Management team biographies

- Discussion of risks and obstacles

- Pro forma financial statements/projections

- Capitalization plan

- Brand development

- Implementation strategy.

The business plan is the fundamental starting point for working effectively with theStartupBoeing consulting team. StartupBoeing provides free review services of the business plan and corresponding financials. We offer constructive suggestions, question assumptions, and challenge the entrepreneur to prove the concept just as prospective investors might. For entrepreneurs requiring assistance in preparing the plan itself, StartupBoeing can suggest advisors worldwide who specialize in such services.

The Structural Plan

The Airline Planning Roadmap (PDF) offers a conceptual sense of the necessary steps in launching an airline from idea through launch.

Business Plan Questions (PDF) provides a list of important questions to consider when writing the business plan.

Brand Foundation Overview (PDF) provides a list of steps to take to position your emerging brand based on your market analysis and a need to differentiate from existing competitors.

Structuring the Plan

The Airline Business Plan Outline (PDF) is a tool for capturing many of the important elements for successfully starting and operating an airline. While it is not a comprehensive structure for all airline concepts, it can serve as a starting framework for a business plan.

Airplane Selection

Target markets and frequencies are determined through traffic analysis and route/schedule planning. The startup airline is now positioned to select the appropriate airplane. Included here is basic airplane data a startup-airline can use to make a preliminary aircraft selection and complete a compelling business plan.

Interactive Aircraft Comparator

In-Production Airplanes

Out of production airplanes, passenger airplanes.

- 727 (727-100/-100C/-200)

- 737 (737-200/-200C)

- 737 (737-300/-400/-500)

- 737 (737-600/-700/-800/-900ER)

- 747 (747-100/-200/-300/SP)

- 747 (747-400/-400ER)

- 757 (757-200/-300)

- 767 (767-200/-200ER/-300/-300ER/-400ER)

- 777 (777-200/-200ER/-200LR/-300/-300ER)

Freighter Airplanes

- 707-320C Freighter

- 727-100/-200 Freighter

- 737-200/-300 Freighter

- 747-200F/-200SF/-100SF

- 747 Freighter (747-400/-400ER)

- 757-200 Freighter

- DC-8 Freighter

- DC-9 Freighter

- DC-10 Freighter

- MD-11 Freighter

Boeing Converted Freighters

- 747-400 BCF

Airplane Support

Visit Boeing Support and Services to learn more about Boeing global customer support, including spares & logistics support, maintenance and engineering services, fleet enhancements and modifications, and flight operations support.

The Boeing Airport Compatibility Group assists the aviation community to address their airport-related issues regarding our airplanes, providing Boeing and McDonnell Douglas commercial airplane product information needed to promote the continued and timely development of the world's airports.

Boeing provides a variety of documents that provide Airplane Characteristics data for General Airport Planning . Sections within each document include airplane description, airplane performance, ground maneuvering, terminal servicing, operating conditions, and pavement data.

Learn more about the pallets and containers used to carry cargo on-board large Boeing aircraft, including specific designations, dimensions, descriptions and visuals.

View a glossary of airplane terms .

Airplane Sourcing

Selecting the optimal airplane based on market, network plan, traffic estimates, interior layout, economics, and performance requirements is a good start. But now the airline entrepreneur must source the airplane. Decisions must be made about lease-versus-buy and new-versus-used. Airplane availability may be a challenge. Such factors may drive the airplane selection or even change the business model.

An important first step in sourcing the airplane is to consider financing options . The two most common methods of financing airplanes are direct purchase and operating lease.

New Airplanes

Depending on current production line availability, financing, business plan, and desired launch date, a startup airline may consider purchasing a new production airplane.

Leasing New or Used Airplanes

Boeing works with major airplane leasing companies worldwide. StartupBoeing is able to match qualified startup airlines with Boeing's leasing partners.

Lease Rates

Boeing does not regularly track airplane market lease rates. However, a range of lease rates can be provided to qualified startup airlines.

Through Boeing Commercial Aircraft Customer Finance, qualified startup airlines can be matched with third party sellers/lessors of used airplanes.

Third Party Used Airplanes

Through Boeing's internal Trading Floor, qualified startup airlines can be matched with third party sellers/lessors of used airplanes. Other sources of used airplane availability include:

Operating Your Airline

Boeing offers startup airlines the industry’s largest portfolio of commercial aviation support and services essential for running a successful airline. Through Boeing Global Services startup operators have access to everything from training and interior modifications to aircraft maintenance and high-tech enhancements.

The following solutions are available to suit your specific startup plans and requirements.

Maintenance & Parts Solutions

Boeing’s Maintenance and Part solutions help you to manage maintenance, modification, repair, overhaul and upgrades of your fleet while simplifying your supply chain. One of the services most applicable to a new airline is Global Fleet Care.

Boeing’s Global Fleet Care gives you the most comprehensive maintenance program available.

Global Fleet Care can:

- Help a new entrant operator conserve startup maintenance program capital

- Provide a competitive hourly maintenance rate that reduces airline staffing requirements.

- Include initial parts provisioning

- Supply engineering services

- Provide 24/7 Customer Support and Airplane Health Monitoring

Flight Operations Solutions

Boeing’s Flight Operations Solutions provide full flight operations support that is scalable to grow as your airline expands and your operational complexity increases. From pilot training to start of operations and beyond, our suite of products will provide the highest quality tools for your crews to deliver an efficient flight operation.

Services most applicable to a new airline:

- Flight Planning

- Charts and Navigation

- Electronic Flight Bag (EFB)

- Pilot training and Simulator

- Performance Planning

Boeing Aviation Consultants

Boeing’s staff of experienced airline and consulting professionals can advise and assist with all activities associated with a new entrant airline.

Boeing’s Consultants can:

- Assist with securing an Air Operator Certificate (AOC) as well as other regulatory requirement filings

- Design and structure an efficient operations organization

- Advise in the development and regulatory approval of a maintenance program

- Design a parts optimization program

- Assist with route analysis and payload improvements

- Develop a fuel efficiency program

- Select Information Technology elements that are appropriate for the size of operation

- Prepare an airline for eventual transition to ‘smart’ airplanes

Once an airline is up and running, Boeing’s Aviation Consultants can also provide periodic, detailed operations analysis that can assist with optimizing your maintenance and fuel efficiency programs, as well as provide crew management solutions for best scheduling and utilization of crewmembers.

When you are ready to start your airline, Boeing is ready to help you every step of the way.

Boeing offers startup airlines a comprehensive array of tools and services for running a successful airline. Everything from training to interior design to financing to maintenance to high-tech enhancements and more. Available resources include:

- Aviation Partners Boeing : Fuel saving and performance enhancing Blended Winglets for a number of current production Boeing airplanes and out-of-production models

- Boeing Business Jets : Private, Business, and Government VIP configured Boeing production airplanes

- Boeing Support and Services : Customer Support, Material Management, Maintenance Services, Fleet Enhancement, Flight Operations

- Fuel Conservation Services : Optimizing your operations to maximize airplane fuel efficiency

- Jeppesen : Aviation Training, Charts & Navigation Services, Flight Planning and Custom Services

- Training & Flight Services : Maintenance and Flight Crew Training

Becoming a Customer

Whether you are starting a new airline with Boeing aircraft, adding your first Boeing aircraft to your existing fleet, or you are new to maintaining Boeing aircraft, we have the products, services, and information resources needed to get you off the ground and keep you flying.

Relationship

Creating a business relationship with Boeing can provide access to:

- Boeing expertise

- Support services needed for the introduction, operation and maintenance of your aircraft

What do you need?

If you are a Maintenance Repair and Overhaul (MRO) or repair station, please see the Intellectual Property Management - Licensing Questionnaire .

In order to obtain Boeing goods and services, it will be necessary to enter into an agreement with Boeing and set-up an account. To begin the account set-up process, complete and submit a Boeing Customer Questionnaire . This questionnaire must be completed and submitted electronically.

Upon receipt of the completed questionnaire and based upon the information you submit, Boeing will:

- Start the process of establishing an account so your company can do business with Boeing.

- Assign your company a Boeing customer code which will identify your company within Boeing for future business transactions.

- Identify you as the owner, operator, or lessee of the aircraft.

- Supplemental Agreement for Electronic Access (SA-EA)

- Supplemental Agreement for Electronic Enabling (SA-eE)

- Provide you with certain documents at no charge when the CSGTA and its supplements are signed and appropriate insurance is obtained.

Access to Boeing Part Page

Boeing Material Services offers the advantage of buying from the original equipment manufacturer (OEM).

Boeing also provides customers with access to the aftermarket for a wider breadth of resources to locate hard-to-find parts. From single transactions to supply chain management, Boeing provides you with the right part, at the right place, at the right time. For more access information, please contact [email protected] .

Intellectual Property Management - Licensing Questionnaire

Aircraft owner/operators and third-party service providers have particular needs for OEM products and services as they support the industry. These products and services may require the use of information that is created during the development and certification of Boeing products. Comments from the industry have helped us to establish a set of Intellectual Property licensing standards that address specific requirements and establish a fair and consistent fee structure for the use of the information developed.

Take the Intellectual Property Management - Licensing Questionnaire .

Customer Services General Terms Agreement (CSGTA)

The Customer Services General Terms Agreement (CSGTA) incorporates articles applicable to various Boeing products and services into a blanket-type agreement so that, once in place, only unique terms and conditions need to be negotiated when a customer requires a specific product or service. The benefits of this approach are:

- Faster responses to requests from customers for products and services.

- A reduction in resources and effort needed to implement and manage all Customer Support related agreements for both customer and Boeing.

Some examples of the products and services covered by the CSGTA are lease of parts and tools, purchase of spare parts and standards, retrofit kit changes, repair, modification, technical assistance/consulting, training services and technical data.

Two Supplemental Agreements are associated with the CSGTA. The Supplemental Agreement to the CSGTA for Electronic Access (SA-EA) incorporates articles specific to granting you electronic access to Boeing goods and services, specifically technical data available on MyBoeingFleet.com. The Supplemental Agreement to the CSGTA for Electronic Enabling (SA-eE) incorporates articles specific to software licensing.

Part 125 Airplane Operating Certificate (AOC)

To apply for a part 125 AOC you will need to provide certain documents to your regulatory agency such as the Maintenance Planning Document (MPD), Quick Reference Handbook (QRH), and Aircraft Flight Manual (AFM). Our business operations group will help you get access to these documents on a temporary basis to help you with your AOC application.

MyBoeingFleet (MBF)

MyBoeingFleet is Boeing's secure internet portal, providing authorized customers with access to the industry's most comprehensive range of support products and services for Boeing commercial aircraft.

Aircraft owners and operators - as well as maintenance providers, leasing companies, regulatory agencies and other third party service providers - use MyBoeingFleet to order parts, collaborate with Boeing experts, and obtain essential information such as drawings, documentation, manuals, and operational data and procedures.

Owner/operators and licensed maintenance providers can also access productivity solutions such as Maintenance Performance Toolbox and Airplane Health Management.

Frequently Asked Questions

I want to start an airline. how can the startupboeing site help.

The StartupBoeing site is filled with information that will be useful in starting an airline. In starting an airline, there are specific steps that should be followed, and they are laid out in order to help you along your journey.

- Step 1: Market Analysis

- Step 2: Operating Environment

- Step 3: Business Planning

- Step 4: Airplane Selection

- Step 5: Airplane Sourcing

How can we obtain Boeing aircraft performance data for our planned operations?

The StartupBoeing team has found that this usually is not the first question to ask when starting an airline. The market opportunity and business plan will help shape what aircraft to fly. Once an understanding of the market opportunity and competitive environment are established, the StartupBoeing team can assist in providing suggestions for aircraft and ultimately performance data to fit the market opportunity.

Can Boeing lease me an aircraft?

Boeing generally does not lease aircraft. Aircraft leasing is usually done by third parties not associated with Boeing. To help you find these leased aircraft, Boeing has provided links to these parties found in the Airplane Sourcing section.

I want to buy a used aircraft from Boeing. How much does it cost?

Boeing generally does not sell used aircraft. Used aircraft are usually sold by third parties not associated with Boeing. To help you find these used aircraft, Boeing has provided links to these parties found in the Airplane Sourcing section.

Where can I find information on Boeing airplanes?

Information on passenger and freighter airplanes, along with information on cargo hold sizes can be found in the Airplane Selection section.

Where can I find a definition of aircraft terms?

A glossary of aircraft terms can be found here .

Where can I find airplane market data?

The Boeing Current Market Outlook (CMO) and World Air Cargo Forecast can be found in the Market Analysis section.

Where can I find information on business planning?

Information on business plans can be found in the Business Planning section.

Where can I find information about regulatory requirements?

Information about regulatory requirements can be found in the Operating Environment section.

What is Aerospace Manufacturing? A Comprehensive Guide

The aerospace industry is one of the most advanced and sophisticated industries in the world. It is responsible for the design, development, and production of aircraft and spacecraft, as well as the various systems and components that go into them. Aerospace manufacturing plays a crucial role in this industry, as it involves the creation of these complex and technologically advanced products.

In this article, we will delve into the world of aerospace manufacturing and explore the various processes, technologies, and challenges involved in creating the aircraft and spacecraft that we rely on every day. We will also examine the key players in the industry and the role they play in driving innovation and progress.

What is Aerospace Manufacturing?

Aerospace manufacturing refers to the process of designing, developing, and producing aircraft and spacecraft, as well as their various components and systems. This includes everything from passenger jets and military aircraft to satellites and space probes.

Aerospace manufacturing is a highly specialized field that requires a combination of advanced technological expertise, engineering skills, and precision manufacturing techniques. It is a complex and multifaceted process that involves a wide range of activities, including research and development, design and engineering, prototyping, testing, and production.

Aerospace Manufacturing Processes

The aerospace manufacturing process typically begins with research and development, where engineers and scientists work to identify the needs and requirements for a new aircraft or spacecraft. This can involve extensive research into materials, technologies, and design concepts to determine the best approach for meeting these needs.

Once the research and development phase is complete, the next step is the design and engineering phase. This involves creating detailed blueprints and plans for the aircraft or spacecraft, as well as designing the various systems and components that will be used.

Once the design is finalized, the aerospace manufacturing process moves on to the prototyping phase. In this phase, prototypes of the aircraft or spacecraft are built and tested to ensure that they meet the necessary performance and safety standards. This can involve extensive testing in simulated environments, such as wind tunnels and flight simulators, as well as physical testing on the ground and in the air.

If the prototypes are successful, the next step is the production phase. This involves creating the final aircraft or spacecraft using advanced manufacturing techniques, such as CNC machining, 3D printing, and laser cutting. The finished products are then inspected and tested to ensure they meet all the necessary specifications and standards.

Aerospace Manufacturing Technologies

Aerospace manufacturing relies on a wide range of advanced technologies and techniques to design and produce aircraft and spacecraft. Some of the key technologies used in aerospace manufacturing include:

- 3D printing: 3D printing, also known as additive manufacturing, is a process that involves creating a physical object by depositing layers of material according to a digital design. This technology has been used in aerospace manufacturing to create complex parts and structures that would be difficult or impossible to produce using traditional manufacturing techniques.

- CNC machining: CNC machining is a process that involves using computer-controlled machines to cut, shape, and finish materials, such as metal and plastic. This technology is widely used in aerospace manufacturing to create precise and complex parts and components.

- Laser cutting: Laser cutting is a process that involves using a focused beam of light to cut through materials, such as metal and plastic. This technology is often used in aerospace manufacturing to create precise and intricate parts and components.

- Composites: Composites are materials made from a combination of two or more materials, such as fiberglass and epoxy.

Key Players in the Aerospace Manufacturing Industry

The aerospace manufacturing industry is made up of a diverse range of companies, from small startups to large multinational corporations. Some of the key players in the industry include:

- Boeing: Boeing is one of the largest aerospace companies in the world, with a long history of designing and manufacturing aircraft and spacecraft. The company is known for its commercial aircraft, military aircraft, and space systems.

- Airbus: Airbus is a major player in the aerospace industry and is known for its commercial aircraft, as well as its military and helicopter products. The company has a global presence and is headquartered in Europe.

- Lockheed Martin: Lockheed Martin is a leading aerospace and defense company that designs and manufactures a wide range of products, including aircraft, spacecraft, missiles, and defense systems.

- Raytheon Technologies: Raytheon Technologies is a global aerospace and defense company that specializes in the design and production of aircraft and spacecraft components, as well as missile defense systems and other defense technologies.

Challenges in Aerospace Manufacturing

Aerospace manufacturing is a complex and challenging field, and there are several key challenges that companies in the industry must overcome. Some of these challenges include:

- Meeting regulatory requirements: Aerospace products must meet strict safety and performance standards, and companies must navigate a complex regulatory landscape in order to bring their products to market.

- Managing supply chain risks: Aerospace manufacturing involves working with a wide range of suppliers and partners, and companies must carefully manage their supply chains in order to ensure that they have access to the materials and components they need.

- Ensuring quality and reliability: Aerospace products must be of the highest quality and must be reliable in order to ensure the safety of passengers and crew. This requires strict quality control processes and robust testing protocols.

- Managing costs: Aerospace manufacturing is a capital-intensive industry, and companies must carefully manage their costs in order to remain competitive. This can involve leveraging advanced technologies and processes to improve efficiency and reduce waste.

The Future of Aerospace Manufacturing

The aerospace industry is constantly evolving, and the field of aerospace manufacturing is no exception. In the coming years, we can expect to see a number of exciting developments in the industry, including:

- Increased use of advanced technologies: As mentioned earlier, aerospace manufacturing relies on a wide range of advanced technologies, and we can expect to see continued innovation in this area. This may include the increased use of 3D printing, advanced materials, and other technologies to improve efficiency and reduce costs.

- Greater emphasis on sustainability: As the aerospace industry looks to reduce its environmental impact, we can expect to see a greater focus on sustainability in aerospace manufacturing. This may involve the use of more environmentally-friendly materials and processes, as well as the development of more fuel-efficient aircraft.

- Continued globalization: The aerospace industry is a global industry, and we can expect to see continued globalization in aerospace manufacturing. This may involve the development of new manufacturing hubs in emerging markets and the expansion of existing facilities in established markets.

In conclusion, aerospace manufacturing is a complex and multifaceted field that plays a crucial role in the aerospace industry. It involves the design, development, and production of aircraft and spacecraft, as well as their various systems and components. Aerospace manufacturing relies on a wide range of advanced technologies and techniques, and is constantly evolving to meet the changing needs and requirements of the industry. The key players in the industry include companies such as Boeing, Airbus, Lockheed Martin, and Raytheon Technologies, and they face a number of challenges, including regulatory requirements, supply chain risks, and cost management.

Stay up to date with aerospace news.

Recent stories.

.jpg)

Skyward Journey: The Essential Role of EMI Aerospace in Advancing Aerospace Technology

Reimagining the future of aviation with innovative solutions and state-of-the-art engineering techniques.

The Importance of Aerospace Trade Publications: A Comprehensive Guide

Aerospace trade publications provide valuable information and insights for professionals in the industry, covering topics such as aircraft and spacecraft design, aviation and space news, and industry trends and developments.

The Fascinating World of Aerospace Production: A Comprehensive Guide

Aerospace production is a crucial aspect of the aerospace industry, involving the creation of aircraft and spacecraft, as well as their various components and systems. It is a complex and multifaceted process that requires a combination of advanced technological expertise, engineering skills, and precision manufacturing techniques.

- Resources for Entrepreneurs > Good Business Ideas > Starting a Business

Opening an Aircraft Parts & Equipment Wholesale & Manufacturing Business

Starting a Business

If you are interested in starting an aircraft parts and equipment wholesale and manufacturing business, priority one is defining your value proposition.

We offer several relevant recommendations on how to start an aircraft parts and equipment wholesale and manufacturing business.

Best Aircraft Parts & Equipment Wholesale & Manufacturing Company Business Plans

How good is your aircraft parts and equipment wholesale and manufacturing company's business plan? If you aren't completely confident in the quality of your business plan, it could be because you haven't invested enough time and effort in its creation.

Although there are a lot of tasks screaming for your attention, cutting corners on your business plan can be a precursor to disaster. Why? Because there are a multitude of reasons why your company can't succeed without a sound business plan .

From a business ownership perspective, that makes business planning your first priority - and not a task that can be assigned to the back burner.

Look Over Competitors

Prior to launching an aircraft parts and equipment wholesale and manufacturing business in your town, it's worthwhile to determine what the competition looks like. We've provided the link below to help you get a list of local competitors nearby. Simply enter your city, state and zip code to get a list of aircraft parts and equipment wholesale and manufacturing businesses in your town.

- Find Competing Aircraft Parts & Equipment Wholesale & Manufacturing Businesses

It's important to be aware of what the competition is doing. Take the time to visit the competition to properly assess their strengths and weaknesses.

A Good Source of Advice

Once you've finished assessing the competion, it's a smart move to speak with somebody who is already in the business. Local competitors are not going to give you the time of day, mind you. Why would they want to educate a future competitor?

On the other hand, an individual who has an aircraft parts and equipment wholesale and manufacturing business in another town may be more than happy to give you a few tips, as long as they don't view you as a competitive threat. Many business owners are happy to give advice to new entrepreneurs It can take a while to find an entrepreneur who is willing to talk, but it's well worth the effort.

Where does one find an owner of an aircraft parts and equipment wholesale and manufacturing business on the other side of the country to talk to?

We can help. Follow the link below, try a few city/state combos or zipcodes, and then start calling!

- Find an Experienced Aircraft Parts & Equipment Wholesale & Manufacturing Business Entrepreneur

Business Brokerage for Aircraft Parts & Equipment Wholesale & Manufacturing Business Entrepreneurs

Business owners are decision makers. And the first decision you'll need to make is between an aircraft parts and equipment wholesale and manufacturing business startup and an acquisition. Unless you have specific business objectives that require a startup approach, you're probably better off trying to buy an established aircraft parts and equipment wholesale and manufacturing business.

A qualified business brokers can provide a range of services designed to ease your transition into business ownership.

The best business brokers will ensure that you get the right business for the right price, and will help you avoid common aircraft parts and equipment wholesale and manufacturing business acquisition mistakes.

Is Franchising the Right Option?

Your chances of achieving the entrepreneurial goal of becoming a successful entrepreneur zoom upwards if you opt for franchising rather than going it alone.

If you planning on starting an aircraft parts and equipment wholesale and manufacturing business, you would be wise to investigate whether there are good franchise opportunities available that might help you on your entrepreneurial journey.

The link below gives you access to our franchise directory so you can see if there's a franchise opportunity for you. You might even find something that points you in a completely different direction.

- Franchise Directory

Other Useful Articles for Startup Entrepreneurs

These additional resources regarding starting a business may be of interest to you.

How to Find Angel Investors

Share this article

Additional Resources for Entrepreneurs

Lists of Venture Capital and Private Equity Firms Franchise Opportunities Contributors Business Glossary

- Terms of Use

- Privacy Policy

- Entrepreneurial Resources

- Small Business News

- Gaebler France

- Gaebler Mexico

- Gaebler Philippines

- Gaebler Czech Republic

- Gaebler Germany

- Gaebler China

Copyright © 2001-2024. Gaebler Ventures. All rights reserved.

U.S. Government Accountability Office

Commercial Aviation Manufacturing: Supply Chain Challenges and Actions to Address Them

Air travel has rebounded since 2020, increasing airlines' demand for new aircraft and parts for current fleets. Boeing and Airbus—and companies that supply them with parts and materials—have faced challenges increasing production to meet demand.

Aviation manufacturers reported shortages of workforce and materials. Some said they were

offering financial incentives

working with local schools to build interest in aviation careers

increasing oversight of suppliers

adding new suppliers

To adapt to difficulty getting new aircraft and parts, airlines reported reducing the number of flights and working to safely extend the life of some parts.

What GAO Found

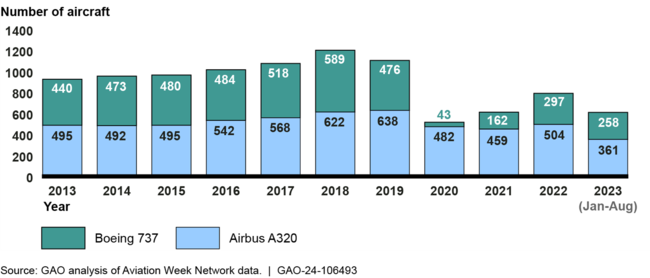

Orders for new commercial aircraft have rebounded since they declined in 2020. However, the two main manufacturers of commercial aircraft—Boeing and Airbus—have faced challenges in increasing production of their most popular models—the Boeing 737 and Airbus A320—to meet demand. Steps Boeing and FAA are taking to ensure safety after a January 2024 in-flight failure of a section of the fuselage have also affected Boeing's production levels early in 2024. Additionally, of the 15 companies GAO interviewed that supply components to Boeing and Airbus, nine said that they have likewise had difficulty filling orders with the rebound in demand following the COVID-19 pandemic.

Estimated Number of Boeing 737 and Airbus A320 Aircraft Produced, 2013–2023

Manufacturers attributed these production challenges to workforce and material shortages and are working to mitigate them. Fifteen of the 17 manufacturers GAO spoke to said they or their suppliers have had difficulty hiring enough skilled workers to enable them to satisfy the demand for their products. Six manufacturers said that difficulty hiring sufficient workers may be related to difficult or hazardous working conditions that some of these jobs entail, such as the use of toxic chemicals. Some manufacturers reported offering financial incentives and working with local schools to build interest in aviation careers to address their workforce needs. Further, fifteen manufacturers said that they or their suppliers have had difficulty procuring materials needed to complete their orders. Material shortages included a broad range of items, such as engines and semiconductors as well as raw materials like aluminum. To address these material shortages, manufacturers said they have increased monitoring of suppliers and established additional sources for some supplies.

Airlines reported making changes to scheduled flights and developing ways to safely extend the life of some parts, among other actions, due to the difficulty obtaining new aircraft or the parts needed to maintain their current fleet. Seven of the eight airlines GAO spoke with reported delays of new aircraft they had expected to receive in 2023, and all eight airlines said they have had trouble obtaining a broad range of parts needed to maintain their fleets. Parts in short supply included small hardware like nuts and bolts as well as specialized items like cockpit windows and engine components.

Why GAO Did This Study